Industral 4.0 training series

Industry 4.0 – the future of production: the new ways in which people, machines and data can interact. the training of Industry 4.0 skilled workers must be adapted to meet the new requirements of this interdisciplinary approach. service technicians not only need practical mechatronics experience but also knowledge of IT infrastructures. Dolang Industry 4.0 learning system – Seamless, modular and expandable Smart Factory Mechatronics Training System,Smart Factory Enterprise Training System,Smart Factory Tabletop Mechatronics Training System and other industry 4.0 equipment. Industry 4.0 system also includes Smart Factory components for Ethernet, RFID/Sensors , Barcode , with a multi-station automated manufacturing system that integrates mechatronics, robotics, conveyors, autonomous robots, and a variety of other Smart Factory technologies.

-

Hot

DLIM-441 Intelligent Manufacturing Training Equipment Industry 4.0 Training System Industry 4.0 Lab

DLIM-441 Intelligent Manufacturing Training Equipment Industry 4.0 Training System Industry 4.0 Lab

This platform is technical teaching equipment Intelligent Manufacturing Training Equipment, it involves knowledge and skills in intelligent control technology, numerical control technology, industrial robot technology, pneumatic technology, sensor technology, electromechanical integration technology, industrial engineering technology, software technology, automation technology, online measurement technology and other fields. The engineering education equipment is used for industry 4.0 training system in industry 4.0 lab, and the educational training equipment uses in vocataion school labs, the technical vocational didactic equipment used in TVET schools and training centers for vocational training equipmenteducational training equipmentindustry 4.0 training system didactic equipment vocational training system industry 4.0 lab vocational training equipmentEmail Details -

Hot

DLIM-441 Intelligent Manufacturing & Industry 4.0 Training Equipment

DLIM-441 The integrated application platform of intelligent manufacturing system takes the digital transformation process of traditional discrete manufacturing enterprises as the task carrier, deploys RFID, intelligent sensors, network equipment and other basic nodes of the Internet of things in the data acquisition layer and network layer, introduces intelligent manufacturing devices such as industrial robots and digital control machine tools in the executive equipment layer, and introduces digital management and control system in the control layer and management layerAt the same time, we will build various open information service platforms, share data resources, and finally realize the functions and ideas of automation, digitization, networking and intelligence of the whole system.

Email Details

This platform involves knowledge and skills in intelligent control technology, numerical control technology, industrial robot technology, pneumatic technology, sensor technology, electromechanical integration technology, industrial engineering technology, software technology, automation technology, online measurement technology and other fields. -

Hot

Digital twin training system

DLIM-DT01B Digital twin technology application platform

Email Details

Using digital twin technology application platform, a virtual simulation system with actual interactive function is created according to the requirements. The simulation system can realize the physical performance, mechanical structure and action function consistent with the actual environment. It can make the mechanical design and electrical design develop in parallel on the simulation system, and eliminate the gap period in the traditional development process.

The simulation system is not only a simple animation scene, but also can interact with the actual control equipment, receive control instructions and feedback signals from sensors, etc. during the simulation process, it can timely discover various problems in the operation of the equipment under program control and carry out optimization, so as to improve the design efficiency and reduce the cost and risk.

In response to the above situation, the State Council issued notice on Issuing the plan for the implementation of the national vocational education reform (Guo Fa [2019] 4), pointing out that we should adapt to the development demand of "Internet plus occupation education", improve the teaching methods and methods with modern information technology, and promote the construction and application of virtual learning network occupation space, and complement and expand the offline practical training teaching activities. -

DLIM- 4212 Lean Automation Technology Application System

The system closely focuses on the latest technological development trend of "Industry 4.0", and integrates "Internet +", "smart sensors", "PLC control technology", "intelligent electromechanical equipment", "digital twin simulation", "logistics technology", "IT Advanced technologies,Information safety, and Lean Automation”, which can enable students to learn and master the latest knowledge and skills of Industry 4.0.

Email Details -

DLIM-732 Service Manufacturing Technology Platform(Industry 4.0 Training System)

Equipment composition and function description:

Email Details

Device workflow:

1) Data management unit: order management and data display

2) Automatic feeding unit: According to the requirements, the workpiece is pushed out of the bin by the feeding cylinder, and the handling manipulator transports the pushed workpiece to the conveyor belt of the sorting unit, and scans the workpiece bottle for inspection.

3) Intelligent sorting unit: The conveyor belt transports the workpieces of the previous station to the stop position, and completes the canning of 5mm or 8mm steel balls according to the order requirements. The gear stop mechanism resets, and the finished workpiece enters the next workstation. -

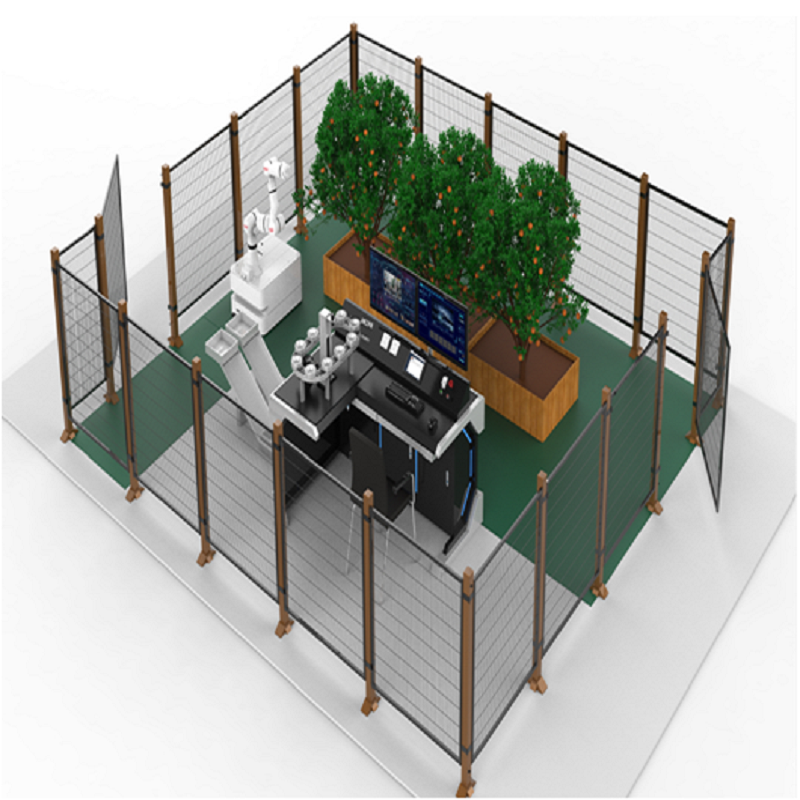

DLAI-1221A Artificial Intelligence Comprehensive Training and Assessment System

DLAI-1221 artificial intelligence comprehensive training and assessment system is one kind of AI technical teaching equipment, the training and assessment platform developed based on the above requirements. The platform consists of a high-performance computer, a mobile terminal development module, a data sampling and testing module, a computer vision detection module, a Habot collaborative robot module, an AMR robot based on QR code navigation, and an application scenario simulation module. The software platform is based on Windows (optional Linux Ubuntu 18.04) with pre-installed modules such as Anaconda, Python, YOLOv5, OpenCV, and PyTorch, it's ideal engineer teaching platform for artificial intelligence related course.

The DLAI-1221A artificial intelligence comprehensive training system simulates the intelligent picking process, uses the computer as the intelligent control center, cooperates with high-definition cameras, collaborative robots and AMR inspection robots. Picked by collaborative robots to complete intelligent picking.Artificial Intelligence Comprehensive Training and Assessment System TVET technical teahing bench vocational engineer training equipmentEmail Details -

DLIT-370X Smart Logistics Management and Application Training system

DLIT-370X Smart Logistics Management and Application Training system focuses on security, access control, monitoring, automation operation system (heating, bad border detection, etc.), network communication, and other related content,

This kind of vocational engineer teaching system can complete the relevant training content of the design planning, process layout and installation, system debugging, comprehensive layout planning data collection and monitoring of residential and communities, while meeting the hardware and technical requirements of vocational skills appraisal and related competitions.Smart Logistics Management and Application Training system Intelligent logistics teaching system TVET technical training equipmentEmail Details -

DLIM-729A Intelligent equipment digital system

DLIM-729A Intelligent equipment digital system can assist the scientific research work of colleges and universities. It has many advantages in experimental training teaching, such as easy to teach, easy to learn, low teaching cost, high utilization rate, easy to maintain and high safety.

Intelligent equipment digital system technical teaching equipment electro hydraulic training system refrigeration trainer aircon servicing courseEmail Details -

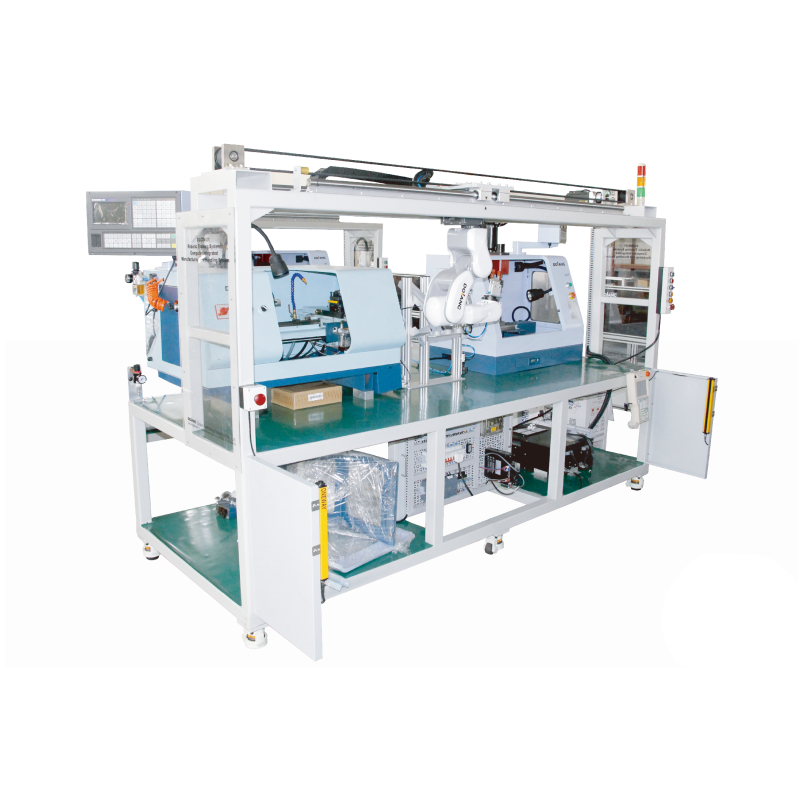

DLCIM-01 Computer Integrated Manufacturing Training System

DLCIM-01 Computer Integrated Manufacturing Training System is an industry 4.0 teaching system and vocational training equipment,not only to meet the requirements of professional teaching, but also can exercise students to a variety of disciplines and comprehensive use of knowledge and system thinking ability.

This training system integrate industrial robots, programmable controllers, servo motors, sensors and organic integration in one of the training systemComputer Integrated Manufacturing Training System vocational technical teaching system TVET engineer teaching systemEmail Details