MPS Training Series

The mps training system covers the multi-disciplinary comprehensive knowledge involved in the integration of mechanical, electricity, light and gas, which can minimize the gap between the training process and the actual production process. The technologies of the Modular Production System training equipment include: PLC control technology and sensor detection Technology, pneumatic technology, motor drive technology, computer configuration monitoring and human-machine interface, mechanical structure and system installation and debugging, fault detection technology skills, Ethernet communication, touch screen technology, motion control, computer technology and system engineering.

-

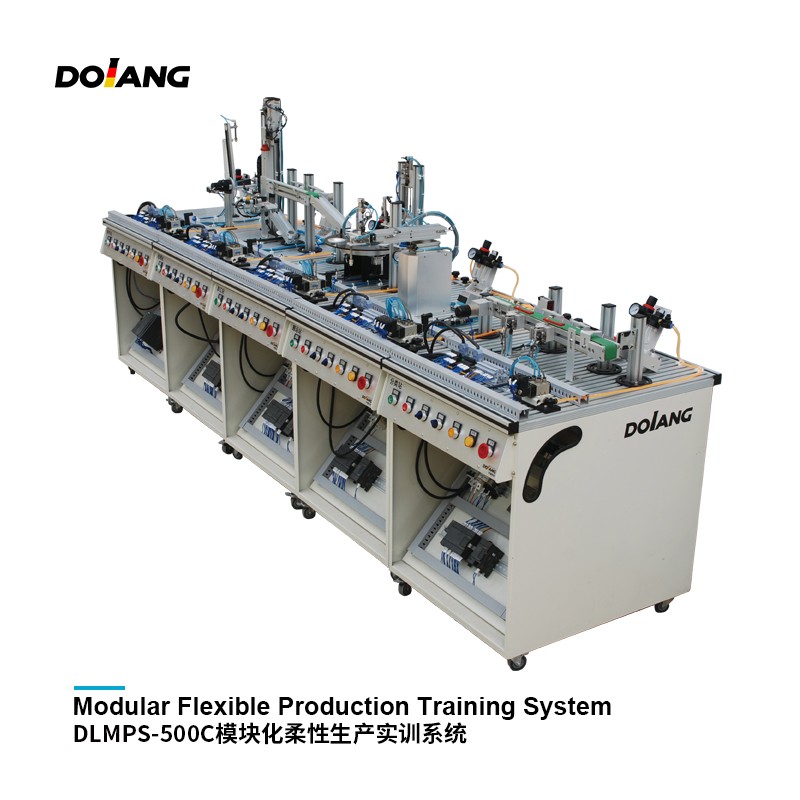

DLMPS-500C Modular Production System Industry 4.0 Training Kits from Dolang Didactic Equipment

Industry 4.0 MPS Learning Systems is designed for training in vocational skills and technical knowledge in the area of automation technology and mechatronics. Modular Systems for Mechatronics Training, used in technical vocational education training.(TVET)

Email Details

Advanced equipment technology: This equipment combines the actual control requirements of the industrial site, and the concentrated expression of various elements on the equipment provides students with a broad training space and comprehensively and systematically masters the frontier knowledge of various disciplines. -

DLMPS-500B MPS Training System Modular Flexible Production Didactic Equipment

Dolang training system MPS series is designed for training in basic skills and specialist knowledge in the area of automation technology and mechatronics. MPS Learning Systems. Modular Systems for Mechatronics Training. MPS Modular. Production System. Model industrial automation systems at various levels.

Email Details

1. Device intuitiveness

2. Networking of equipment

3. Advanced equipment technology: This equipment combines the actual control requirements of the industrial site, and the concentrated expression of various elements on the equipment provides students with a broad training space and comprehensively and systematically masters the frontier knowledge of various disciplines.

4. Combination of concentrated and divergent thinking:

5. Configurability: The device passes the configuration principle of each substation through the touch screen, and integrates the control of each station through the management of the main control unit.

6. The operability of the system: each work unit can be operated independently, that is, it can be connected to the Internet and work offline. -

DLMPS-600B Technical Vocational Educational Modular Flexible Production Line MPS Training System

Dolang is manufacutre for vocational training equipment, with rich experiences on didactic equipment, Dolang have good reputation in the world.

Email Details

The DLMPS-600B mps training system nvolved in the integration of machine, electricity, light and gas, which can minimize the gap between the training process and the actual production process. The technologies involved include: PLC control technology and sensor detection. Technology, pneumatic technology, motor drive technology, computer configuration monitoring and human-machine interface, mechanical structure and system installation and debugging, fault detection technology skills, Ethernet communication, touch screen technology, motion control, computer technology and system engineering. -

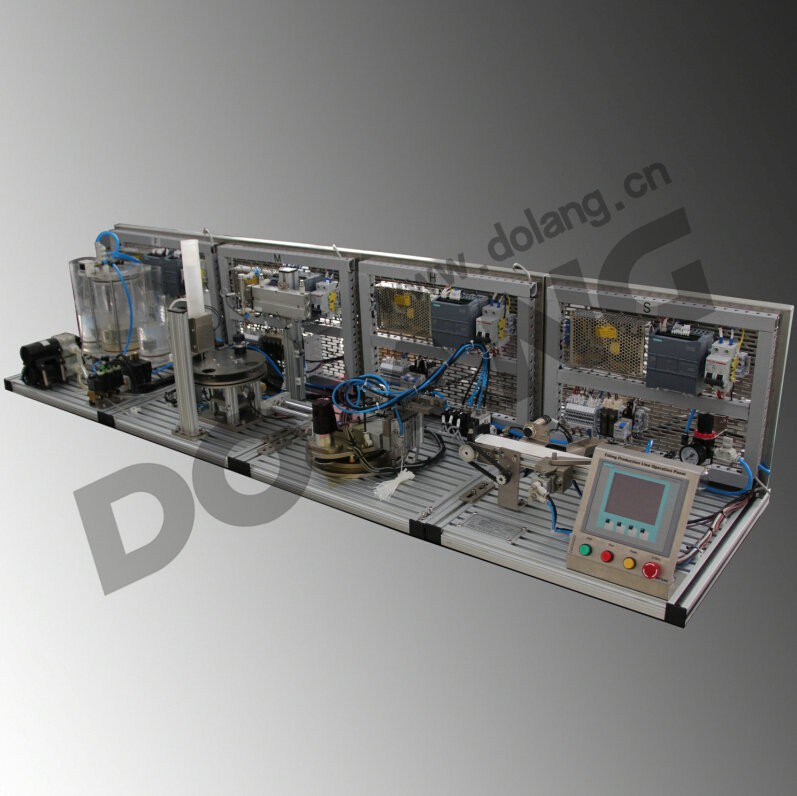

DLPCS-400 Filling Production Line Training System of vocational education equipment

This equipment combines the actual control requirements of the industrial site, and is oriented by modular design. It uses modern PLC control technology, sensor technology, optical technology, mechanical transmission principle technology, pneumatic technology, stepping control technology, and other elements to concentrate on the equipment. It reflects that it provides students with a broad training space and comprehensively and systematically masters the frontier knowledge of various disciplines.

Email Details

1. Intuitiveness: The main equipment is installed directly exposed, and the equipment can be displayed in front of students more intuitively.

2. Miniaturization: The size of each station is 450mm×460mm×390 mm, which saves laboratory space and is easy to carry.

3. Modularization: Only through the network cable and simple mechanical docking, the assembly of a filling production line can be completed. Real-time is relatively strong.

4. Flexibility: Each station can operate independently or as a part of the production line.

5. Safety: Each station is equipped with an independent circuit breaker with short circuit and overload protection. -

DLMPS-600B Modular flexible production system

The system adopts a modular design of independent units, completes with electrical bus and mechanical bus, and finally connects between modules (stations). Each unit module (station) can work independently, and various system units can be connected in various ways Process requirements, assembling, and connecting into a variety of different training models through the electrical bus; all the control signals and power signals of the controllers, sensors, and actuators are led to the interface unit, and the interface has a specially designed misoperation protection circuit. It can ensure the safety of people and machines.

Email Details -

DLMPS-500A Modular flexible production system

1. Device intuitiveness

Email Details

2. Networking of equipment

3. Advanced equipment technology: This equipment combines the actual control requirements of the industrial site, and the concentrated expression of various elements on the equipment provides students with a broad training space and comprehensively and systematically masters the frontier knowledge of various disciplines.

4. Combination of concentrated and divergent thinking:

5. Configurability: The device passes the configuration principle of each substation through the touch screen, and integrates the control of each station through the management of the main control unit.

6. The operability of the system: each work unit can be operated independently, that is, it can be connected to the Internet and work offline. -

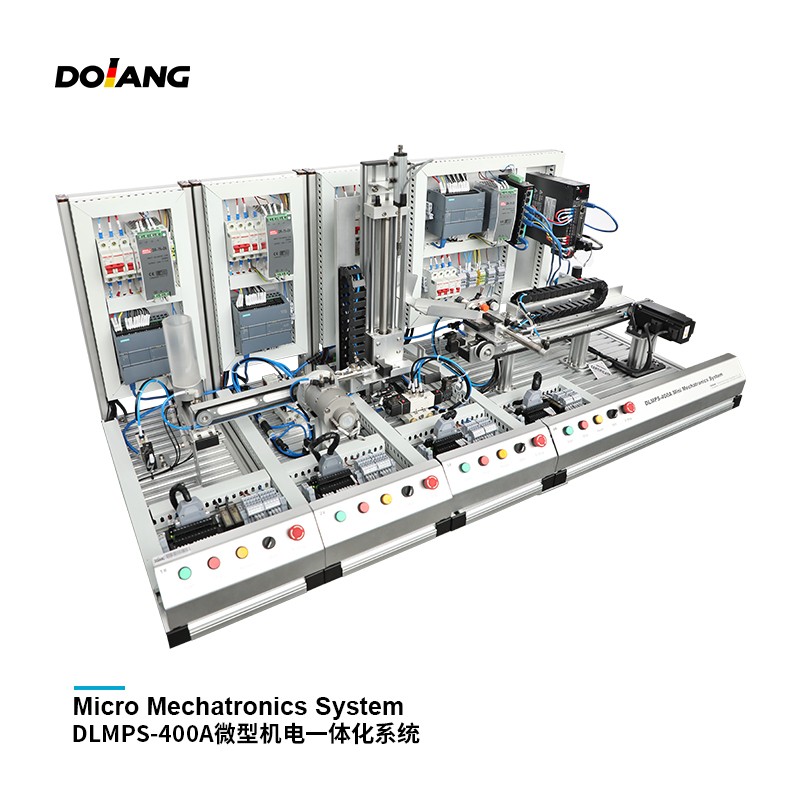

DLMPS-400A Mini Mechatronics System Intelligent manufacturing lab teaching equipment

This mechatronics training system uses Siemens PLC programmable controller as the main controller, and the upper computer realizes configuration monitoring. A complete control system is composed of 4 independent actuators.

Email Details

Siemens PLC is used as the main control, and the PC realizes configuration monitoring

The external port can be used for different types of PLC and can be used for secondary development

4 independent unit actuators, each unit has its own actions and requirements, and can be programmed in groups or in groups -

DLMPS-205 Modular Flexible Production System of vocational education equipment

The DLMPS-205 flexible manufacturing training system consists of a feeding station, a testing station, a handling station, an extrusion station and a sorting station. Each station is installed on a slotted aluminum substrate, and each station can be easily connected together to form an automatic Processing production line. Each station is a modular structure, each module is easy to build, disassemble and maintain, and each workstation can be combined at will.

Email Details -

Hot

DLMPS-800A MPS Machatronics Training system of Industry 4.0

1. Instictive: Main equipment use directly exposed installation form, the device can be more intuitive to show to students, shortening the adaptation time of students from the classroom to the industrial site.

Email Details

2. Networking: PROFIBUS-DP acting as main line of network control system, the field device control layer act as a secondary line, the entire device follow the command of the supreme commander, while allowing each branch independently finish assigned tasks. The general control station is the leader of device and each unit is branch.3. Advanced technology: the device combines industrial practical control requirement, based on module design, use technologies like PLC control technology, sensor technology, optical technology, mechanical transmission technology, pneumatic technology, servo control technology, stepper control technology etc, provide extensive practical training to students.

4. Comprehensive: Master control station stands for focus thinking, and each sub-station stands for divergent thinking, they can work indepently and also can group management.

5. PC configuration: through the computer platform, combine various sub-station via configuration principle, each station will be controlled together by the teacher machine.

6. Easy to operate: Each work unit both can indepently operate and can be combined to network operation