cyber intelligent manufacturing training system

-

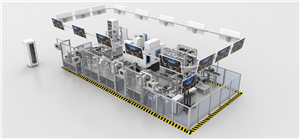

DLFMS-1700B Modern Industrial Production Assembly Training System

The stations of the system are installed on aluminum profile panels, and the stations can be easily connected together to form an automatic processing line. The production line is controlled by a Siemens PLC system, and the stations are connected through Ethernet bus communication. Highly integrated Highly open Modular High scalability Flexibility

plc trainer equipment Modern Industrial Production Assembly Training System indsutrial 4.0 training system IR 4.0Email Details -

DLJS-X1806 Smart Manufacturing (photo frame) Automated Production Line System of vocational education equipment

1) The equipment is complete, which can be applied to the production, application and training of different processes such as storage, machining, marking, 3D printing, assembly testing, packaging and transshipment of three kinds of photo frames. 2) The process unit has a clear distribution and modular design, which is convenient for observation, debugging and teaching guidance in the production process. 3) Flexible connection between processes, which can adapt to the simultaneous production of various products and the adjustment and switching between product processes. 4) Fully automatic control, automatic production and demonstration according to the set parameters. 5) MES intelligent management, which can comprehensively manage the materials, finished products, production, equipment, personnel, orders, etc. 6) practical production design, can be applied to the actual production of photo frames. 7) Factory layout, high security, humanized control station to ensure full monitoring of equipment movements.

vocational education equipment Smart Manufacturing (photo frame) Automated Production Line System indsutrial 4.0 training system IR 4.0Email Details -

Smart Manufacturing (flashlight) Automated Production Line Training System

1.It makes up for the shortcomings of traditional training equipment.using the practical industrial field components and close to the modern industrial production environment ,can enable students to fully understand the organization and control methods of industrial field equipment. 2. Modular design structure: each station is an independent individual, can work alone and combine with other station to work together, students can learn from simple to complex knowledge, from shallow to deep knowledge, step by step. Practice has proved that such a system is of great help to students in the overall development of technology, and at the same time, cultivates the team awareness of students. 3. Integrating today's cutting-edge technologies: PLC, AGV, machine vision, robotic quick change technology, detection and sensing technology, CNC machining, industrial robots, fieldbus, industrial configuration software, modern logistics technology, laser marking, etc. Note: 1. Each station can complete teaching sub-items and teaching demonstrations independently; 2. Each station can be linked to complete the teaching project and teaching demonstration.

virtual trainer modern factory training system Industrial 4.0 with 3D simulation training system Industrial 4.0 with MESEmail Details