indsutrial 4.0 training system

-

Hot

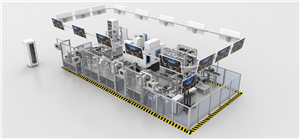

DLIM-441 Intelligent Manufacturing Training Equipment Industry 4.0 Training System Industry 4.0 Lab

DLIM-441 Intelligent Manufacturing Training Equipment Industry 4.0 Training System Industry 4.0 Lab This platform is technical teaching equipment Intelligent Manufacturing Training Equipment, it involves knowledge and skills in intelligent control technology, numerical control technology, industrial robot technology, pneumatic technology, sensor technology, electromechanical integration technology, industrial engineering technology, software technology, automation technology, online measurement technology and other fields. The engineering education equipment is used for industry 4.0 training system in industry 4.0 lab, and the educational training equipment uses in vocataion school labs, the technical vocational didactic equipment used in TVET schools and training centers for vocational training equipment

educational training equipmentindustry 4.0 training system didactic equipment vocational training system industry 4.0 lab vocational training equipment technical vocational indsutrial 4.0 training systemEmail Details -

Hot

DLIM-441 Intelligent Manufacturing & Industry 4.0 Training Equipment

DLIM-441 The integrated application platform of intelligent manufacturing system takes the digital transformation process of traditional discrete manufacturing enterprises as the task carrier, deploys RFID, intelligent sensors, network equipment and other basic nodes of the Internet of things in the data acquisition layer and network layer, introduces intelligent manufacturing devices such as industrial robots and digital control machine tools in the executive equipment layer, and introduces digital management and control system in the control layer and management layerAt the same time, we will build various open information service platforms, share data resources, and finally realize the functions and ideas of automation, digitization, networking and intelligence of the whole system. This platform involves knowledge and skills in intelligent control technology, numerical control technology, industrial robot technology, pneumatic technology, sensor technology, electromechanical integration technology, industrial engineering technology, software technology, automation technology, online measurement technology and other fields.

industry 4.0 equipment vocational training system training equipment intelligent manufacturing training equipmentEmail Details -

Hot

Digital twin training system

DLIM-DT01B Digital twin technology application platform Using digital twin technology application platform, a virtual simulation system with actual interactive function is created according to the requirements. The simulation system can realize the physical performance, mechanical structure and action function consistent with the actual environment. It can make the mechanical design and electrical design develop in parallel on the simulation system, and eliminate the gap period in the traditional development process. The simulation system is not only a simple animation scene, but also can interact with the actual control equipment, receive control instructions and feedback signals from sensors, etc. during the simulation process, it can timely discover various problems in the operation of the equipment under program control and carry out optimization, so as to improve the design efficiency and reduce the cost and risk. In response to the above situation, the State Council issued notice on Issuing the plan for the implementation of the national vocational education reform (Guo Fa [2019] 4), pointing out that we should adapt to the development demand of "Internet plus occupation education", improve the teaching methods and methods with modern information technology, and promote the construction and application of virtual learning network occupation space, and complement and expand the offline practical training teaching activities.

vocational education vocational training system international cooperation Industrial robot application training systemEmail Details -

DLMPS-500A Modular flexible production system

1. Device intuitiveness 2. Networking of equipment 3. Advanced equipment technology: This equipment combines the actual control requirements of the industrial site, and the concentrated expression of various elements on the equipment provides students with a broad training space and comprehensively and systematically masters the frontier knowledge of various disciplines. 4. Combination of concentrated and divergent thinking: 5. Configurability: The device passes the configuration principle of each substation through the touch screen, and integrates the control of each station through the management of the main control unit. 6. The operability of the system: each work unit can be operated independently, that is, it can be connected to the Internet and work offline.

Email Details -

DLFMS-1700B Modern Industrial Production Assembly Training System

The stations of the system are installed on aluminum profile panels, and the stations can be easily connected together to form an automatic processing line. The production line is controlled by a Siemens PLC system, and the stations are connected through Ethernet bus communication. Highly integrated Highly open Modular High scalability Flexibility

plc trainer equipment Modern Industrial Production Assembly Training System cyber intelligent manufacturing training system IR 4.0Email Details -

DLJS-X1806 Smart Manufacturing (photo frame) Automated Production Line System of vocational education equipment

1) The equipment is complete, which can be applied to the production, application and training of different processes such as storage, machining, marking, 3D printing, assembly testing, packaging and transshipment of three kinds of photo frames. 2) The process unit has a clear distribution and modular design, which is convenient for observation, debugging and teaching guidance in the production process. 3) Flexible connection between processes, which can adapt to the simultaneous production of various products and the adjustment and switching between product processes. 4) Fully automatic control, automatic production and demonstration according to the set parameters. 5) MES intelligent management, which can comprehensively manage the materials, finished products, production, equipment, personnel, orders, etc. 6) practical production design, can be applied to the actual production of photo frames. 7) Factory layout, high security, humanized control station to ensure full monitoring of equipment movements.

vocational education equipment Smart Manufacturing (photo frame) Automated Production Line System cyber intelligent manufacturing training system IR 4.0Email Details -

Hot

DLMPS-800A MPS Machatronics Training system of Industry 4.0

1. Instictive: Main equipment use directly exposed installation form, the device can be more intuitive to show to students, shortening the adaptation time of students from the classroom to the industrial site. 2. Networking: PROFIBUS-DP acting as main line of network control system, the field device control layer act as a secondary line, the entire device follow the command of the supreme commander, while allowing each branch independently finish assigned tasks. The general control station is the leader of device and each unit is branch.3. Advanced technology: the device combines industrial practical control requirement, based on module design, use technologies like PLC control technology, sensor technology, optical technology, mechanical transmission technology, pneumatic technology, servo control technology, stepper control technology etc, provide extensive practical training to students. 4. Comprehensive: Master control station stands for focus thinking, and each sub-station stands for divergent thinking, they can work indepently and also can group management. 5. PC configuration: through the computer platform, combine various sub-station via configuration principle, each station will be controlled together by the teacher machine. 6. Easy to operate: Each work unit both can indepently operate and can be combined to network operation

Email Details