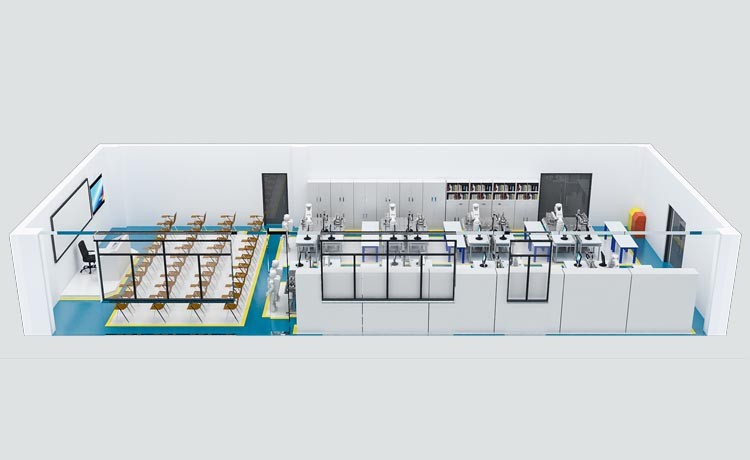

DLGK-373 PCS Educational Training Equipment Level Control Integrated Didactic Equipment Process Control Training System

- Dolang

- China

- 30-60 Days

DLGK-373 Process Control Training Sysetm is an educational training equipment composed by control screen, process control unit. The training system is based on physical modeling objects of industrial processes, which combines automated instrumentation technology, computer technology, communications technology, automatic control technology for multi-function integrated experimental device, the device is based on the enterprise automation and other features related to teaching, absorption characteristics and strengths of domestic and foreign similar experimental device, carefully designed several experiments and repeated demonstration, introduced a new

experimental device, the system including temperature, pressure, flow, level and other thermal parameters can be realized various forms of control system parameter identification, single-loop control, cascade control. The device as a didactic equipment can also be designed according to the needs of users constitute a variety of control systems DDC, DCS, PLC, FCS and SCM. The experimental device can be used as a vocational training equipment for undergraduate, specialist, process control device vocational courses, but also for graduate students and researchers to provide physical simulation objects and experimental methods for the study of complex control systems, advanced control systems.

The system can meet the demand of Training Teaching "Automatic Control Theory", "Process Control", "Automation Instrumentation", "Automatic detection technology and sensors," "Computer Control" and "DCS Distributed Control" and other related courses.

DLGK-373 Process Control Training Sysetm

Equipment Overview

DLGK-373 Process Control Training Sysetm is composed by control screen,process control unit. The training System is based on physical modeling objects of industrial processes, which combines automated instrumentation technology, computer technology, communications technology, automatic control technology for multi-function integrated experimental device, the device is based on the enterprise automation and other features related to teaching, absorption characteristics and strengths of domestic and foreign similar experimental device, carefully designed several experiments and repeated demonstration, introduced a new experimental device, the system including temperature, pressure, flow, level and other thermal parameters can be realized various forms of control system parameter identification, single-loop control, cascade control. The device can also be designed according to the needs of users constitute a variety of control systems DDC, DCS, PLC, FCS and SCM. The experimental device can be used as undergraduate, specialist, process control device vocational courses, but also for graduate students and researchers to provide physical simulation objects and experimental methods for the study of complex control systems, advanced control systems.

The system can meet the demand of Training Teaching "Automatic Control Theory", "Process Control", "Automation Instrumentation", "Automatic detection technology and sensors," "Computer Control" and "DCS Distributed Control" and other related courses.

Technical Parameters

1. Input voltage: single-phase three-wire system 220V±10% 50HZ 2. Working environment: the ambient temperature range is -5~40℃ 3. Device capacity: AC <3000VA 4. Safety protection: leakage protection (action current ≤30mA), overcurrent protection, fuse protection 5. Direct current: DC24V power supply<5A 6. Ambient temperature: -10 ℃ ~40 ℃ 7. Relative humidity: ≤90% (25 ℃) 8. Process control unit dimensions: length×width×height 1500×800×1800 |

Training Content

Section 1. Equipment use training

Training 1 The use of control screen training

Practical training 2 The use of power module training

Practical training 3 The use of smart instrument module training

Training 4 PLC module use training

Practical training 5 The use of analog input module training

Training 6 The use of analog output module training

Practical training 7 The use of inverter module

Training 8 Cognition training of process control unit

Training 9 configuration software training

Training 10 PLC programming software training

Section 2. Inverter training project

Training 11 Inverter pipeline water supply training

Practical training 12 Inverter fixed frequency water supply training (direct selection)

Section 3. Smart instrument training project

Training 13 Configuration software and intelligent instrument communication training

Practicing 14 Practical training of water tank characteristic test (smart meter)

Practical training 15 second-order liquid level object characteristic test (intelligent instrument) training

Training 16 Boiler temperature object characteristic test (intelligent instrument) training

Training 17 Electric control valve flow (smart instrument) characteristic training

Training 18 Pressure PID tuning training (intelligent instrument)

Training 19 Temperature PID tuning (intelligent instrument) training

Training 20 Water tank level PID setting (intelligent instrument) training

Training 21 Flow PID tuning (intelligent instrument) training

Section 4. PLC training project

Training 22 Configuration software and PLC training

Practical training 23 Practical training of upper water tank characteristic test (PLC)

Training 24 second-order liquid level object characteristic test (PLC) training

Training 25 Boiler temperature object characteristic test (PLC) training

Training 26 Electric control valve flow (PLC) characteristic training

Training 27 Pressure PID tuning training (PLC)

Practice 28 Temperature PID tuning (PLC) training

Training 29 Water tank level PID adjustment (PLC) training

Training 30 Flow PID Tuning (PLC) Training

Practical training 31 Dual-capacity liquid level control (PLC) training

Training 32 Upper water tank level and flow cascade control (PLC) training

Practical training 33 Practical training of cascade control (PLC) of the upper and lower tank liquid level

Section 5. DCS training project

Training 34 Analog input module signal acquisition training

Training 35 Application Training of Analog Output Module

Training 36 Configuration software and DCS training

Practice 37 Training on Water Tank Characteristic Test (DCS)

Training 38 Second-order liquid level object characteristic test (DCS) training

Training 39 Boiler temperature object characteristic test (DCS) training

Training 40 Electric control valve flow (DCS) characteristic training

Training 41 Pressure PID tuning training (PLC)

Practical training 42 Temperature PID tuning (DCS) training

Practical training 43 Water tank level PID tuning (DCS) training

Training 44 Flow PID Setting (DCS) Training

Practical training 45 Dual-capacity liquid level control (DCS) training

Training 46 Upper water tank level and flow cascade control (DCS) training

Practical training 47 The cascade control (DCS) training of the upper tank level and the lower tank level

FAQ

Q1. What other services can Dolang provide besides teachingequipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.