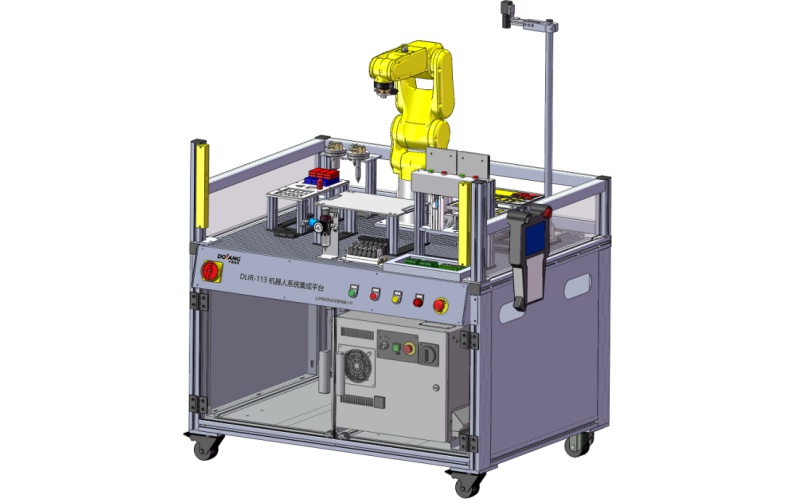

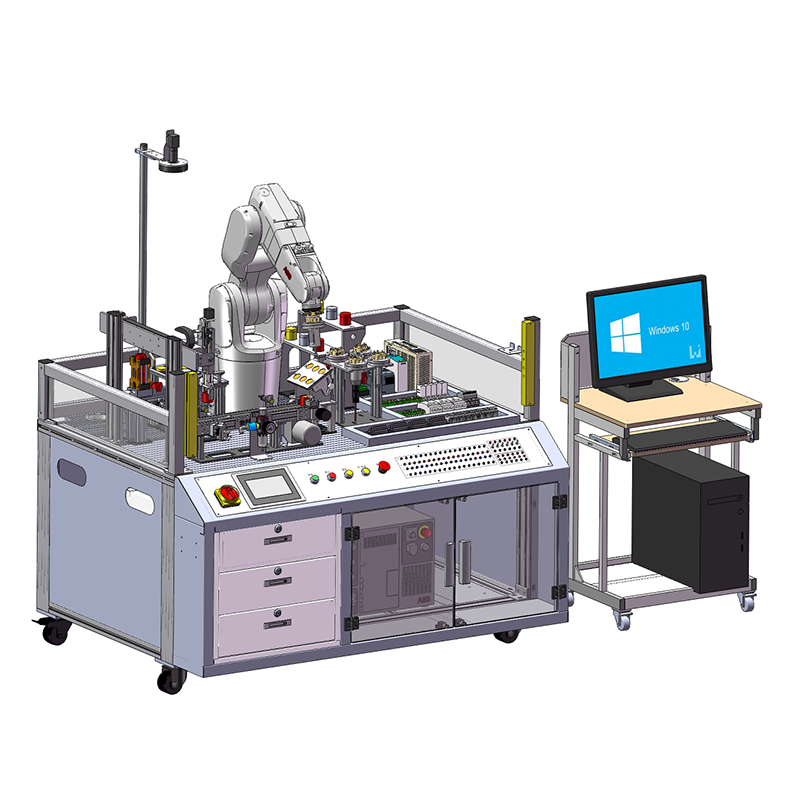

DLCIM-01 IR 4.0 Robot Training System Vocational Educational Equipment

- Dolang

- China

- 30-60 days

Advanced equipment technology: the combination of industrial equipment with the actual control needs to modular design-oriented, the use of modern PLC control technology, sensor technology, optical technology, mechanical different transmission principle technology, pneumatic technology, servo control technology, etc.

DLCIM-01 IR 4.0 Robot Training System Vocational Educational Equipment

Equipment Overview

The IR 4.0 Vocational Educational Equipment adopts module combination, which is mainly composed of storage unit, CNC lathe, CNC milling machine, handling unit, PLC module, servo control module, power module, transfer module and so on, according to the training needs of Robot Training system, the module for a single action or flexible combine and install and commission. Adopt the process involved in the study, such as industrial robot programming, CNC machine programming, motor drive, pneumatic, PLC programming, servo system parameter settings, sensor applications, and many other application technology, to provide students with a typical system Comprehensive training environment

Technical Parameters

1. AC power: single-phase AC220V ± 10% 50Hz

2. Temperature: -10 ℃ ~ 40 ℃; environmental humidity: ≤ 90% (25 ℃)

3. Dimensions: 2810mm × 1500mm × 2100mm (length × width × height)

4. The whole capacity: ≤ 1KVA

5. The control system: Siemens S7-1200 series PLC

6. Industrial robots: MZ04-01-CFD

Training Content

1.Sensor adjustment training;

2.Air connection and commissioning training;

3.Servo motor control training;

4.Air connection and commissioning training;

5.Robot crawl workpiece programming training;

6.Integrated programming debugging training;

7.CNC machine tool precision detection, debugging and principles;

8.CNC machine tool monitoring and compensation technology;

9.CNC machine tool precision debugging;

10.Machine accuracy on-site inspection and analysis;

11.CNC integrated test bed connection and debugging training;

12.CNC device basic connection;

13.CNC system interface awareness and connection;

14.Low voltage control circuit and PLC control and application;

15.CNC system sensor selection and application;

16.CNC machine tool electrical control system design principles;

17.CNC machine running debugging training;

FAQ

Q1. What other services can Dolang provide besides teaching equipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.