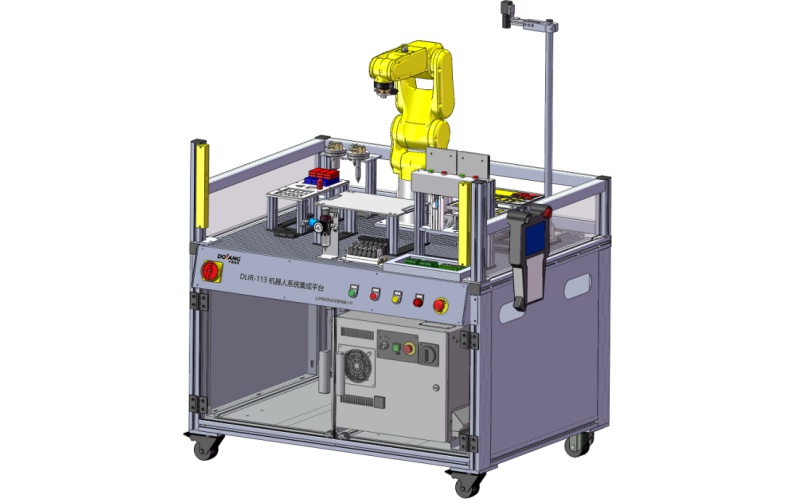

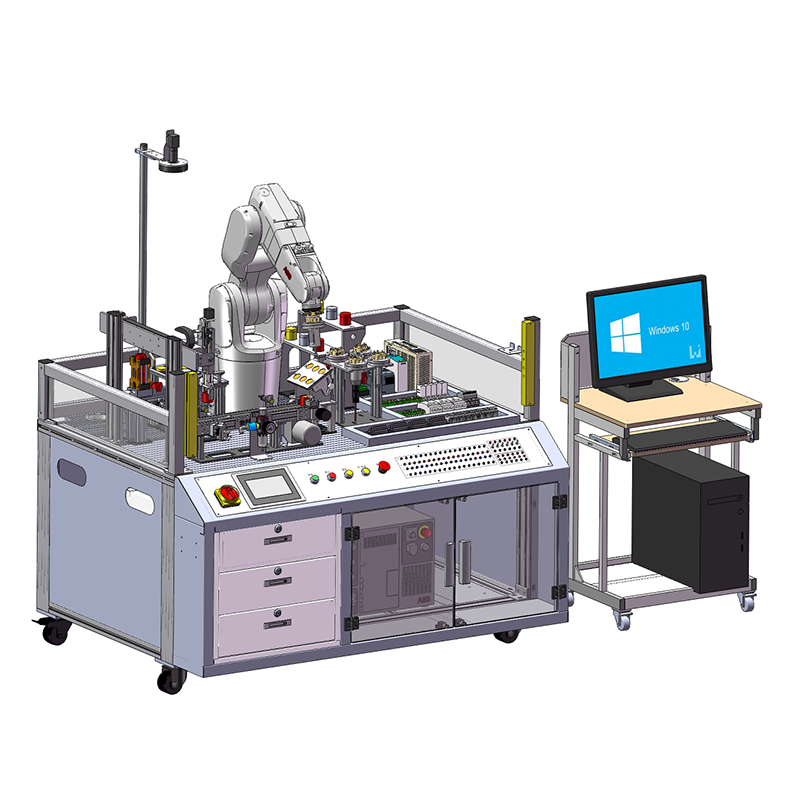

DLDS-1190 Industrial robot system integration training platform

- Dolang

- China

- 40-60 days

The industrial robotics training platform can train students to master the robotics operation, debugging, visual application of industrial robots, PLC principle, PLC programming, sensor technology, PROFINET Industrial Ethernet communication technology, etc.

The industrial robot teaching platfrom may used to realize industrial robot machining automation tasks, intelligent transfer, sorting and stacking tasks of industrial robots, industrial robot gift packaging task, welding task of industrial robot process application, assembly task of industrial robot digital keyboard, robot disassembly training of robot simulation software

1. Overview

DLDS-1190 Industrial robot system integration training platform is mainly composed of FANUC er-4ia industrial robot, Siemens s7-1500 cpu1516-3 pn/dp PLC, FANUC industrial intelligent camera vision system (2D), basic operation assessment module, machining automation task unit, intelligent transfer sorting stacking task unit, gift packaging task unit, process application welding task unit, digital keyboard assembly task unit, etc. The industrial robotics teaching platform can train students to master the industrial robot operation, debugging, visual application of industrial robots, PLC principle, PLC programming, sensor technology, PROFINET Industrial Ethernet communication technology, etc.

2. Technical parameters

2.1 temperature: +5 to +45 °; Ambient humidity: ≤ 85% (25 ℃).

2.2 system floor area: long × wide × Height ≈ 4m × 3m × 2.5mm (width can be adjusted according to site conditions)

3.3 overall power: about 3.5kva.

3.4 altitude: ≤ 4000m.

3.5 input power supply: AC220V ± 10%.

Output power supply: DC24V.

3.6 environment: vibration ≤ 0.5g, no dust, corrosive gas, flammable gas, oil mist, water vapor, dripping water or salt, etc.

3.7 reliable system grounding: grounding impedance < 4 ohms.

3.8 compressed gas pressure: 0.3-0.7mpa.

3.9 cooling mode: natural cooling.

3. Training projects

1) Installation of industrial robots

2) Installation of teaching device for industrial robot

3) Installation of end tools for industrial robots

4) Parameter setting of industrial robot

5) Practical training on operation mode and manual speed of industrial robot

6) Viewing common information of industrial robots

7) Introduction to programming instructions for industrial robots

8) Backup and recovery of industrial robot program

9) Initial power on and IO configuration of industrial robot

10) Practical training of industrial robot coordinate system calibration

11) Setting of safe working area for industrial robots

12) Fault diagnosis and maintenance of industrial robot

13) Practical training of reading electrical drawings

14) Pneumatic circuit connecting pipe and electrical wiring

15) Application of detection switch

16) Application of multiple sensors

17) Application of pneumatic components

18) Installation and application of PLC

19) Installation and application of touch screen

20) Communication between robot and PLC

21) communication between touch screen and PLC

22) practical training of industrial robot and visual communication

23) application of industrial robot quick change tool

24) plane trajectory task of industrial robot

25) industrial robot space trajectory task

26) curved surface trajectory task of industrial robot

27) handling and stacking of square and round blocks by industrial robots

28) handling and stacking task of special-shaped tools (Tangram) of industrial robots

29) industrial robot machining automation tasks

30) intelligent transfer, sorting and stacking tasks of industrial robots

31) industrial robot gift packaging task

32) welding task of industrial robot process application

33) assembly task of industrial robot digital keyboard

34) robot disassembly training of robot simulation software