DLDS-1214B Electrical Installation Training Device

- Dolang

- China

- 30-60DAYS

The electrical installation project refers to the competition methods and competition ideas of the World Skills Competition, and combines the characteristics of practical training and teaching in technical schools.

DLDS-1214B Teaching Aids Electronic Electrical Installation Training System

Equipment Overview

The electrical installation project refers to the competition methods and competition ideas of the World Skills Competition, and combines the characteristics of practical training and teaching in technical schools.

Technical Parameters

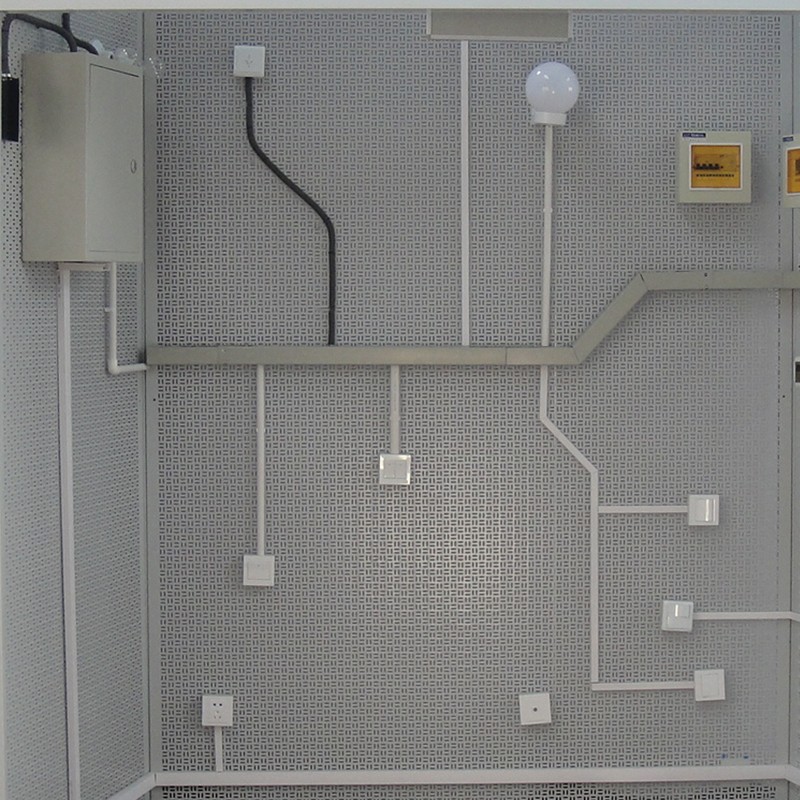

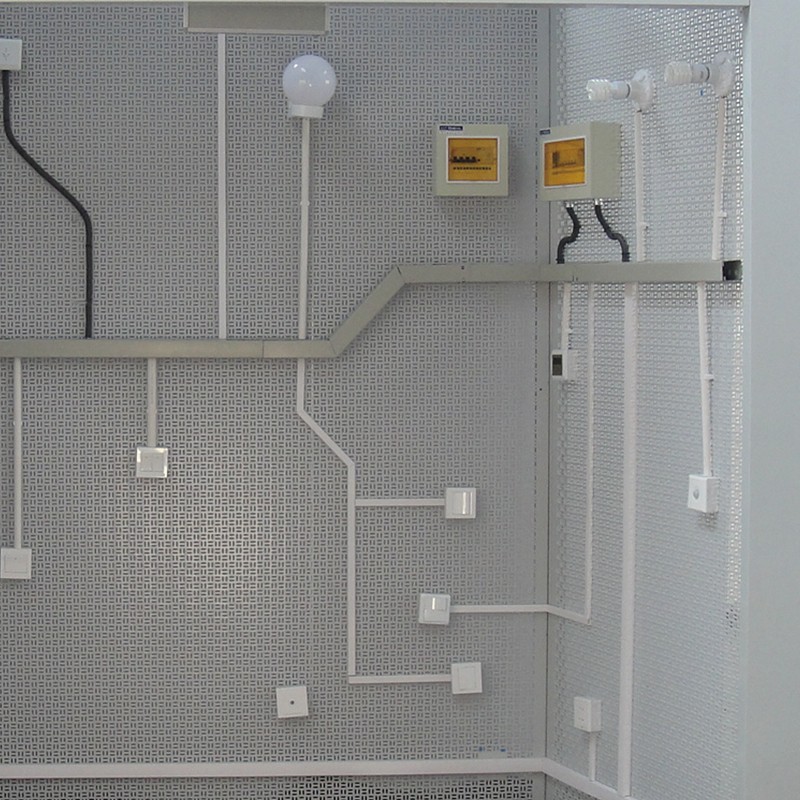

1.Dimension: ladder structure,outer side is established by patch board. Inner established by four simulate wall.

1.1 Left hand (A)/1220mm x 2440 x18 mm

1.2 Right hand (B)/1220mm x 2440 x18 mm

• Main working board (C)/1800mm x 2440 x 18mm

• Ceiling board (D)/former2426mm,behind1827 mm,deepth:1202 mm

2.Operation desk and tools box

Operation desk:1600(L)X700(W)X750(H)

Training Content

1. According to project teaching, mainly complete the following tasks:

2. Basic electrical installation skills training

3. Training on the use of installation tools

4. Training on the use of testing equipment

5. Manual pipe bender processing PVC pipe elbow training

6. PVC pipe, metal pipe cutting training

7. Connection training of plastic electric wire tube and plastic junction box

8. Pipe clamp fixing training

9. Ming piping into box training

10. Shaped bending training of exposed tube

11. Concealed tube fixation training

12. Practical training of embedded iron parts or expansion bolts

13. Bridge support, suspension, bracket production and installation training

14. Operation training of threading inside the tube

15. Connection training of single (multiple) core copper and aluminum wires

16. Indoor lighting and power distribution

17. Socket and a switch control one lamp (incandescent lamp, fluorescent lamp, two-pole leakage switch)

18. Two double switches control one lamp (incandescent lamp, fluorescent lamp, two-pole leakage switch)

19. Three switches control one lamp (incandescent lamp, fluorescent lamp, two-pole leakage switch)

20. Wiring of fluorescent lamp circuit

21. Voice-activated switch controls the wiring of the incandescent lamp circuit

22. Touch the delay switch to control the wiring of the incandescent lamp circuit

23. The human body induction switch controls the wiring of the incandescent lamp circuit

24. Electrical control

25. Asynchronous motor jog control circuit

26. Two-place control circuit of asynchronous motor

27. Asynchronous motor interlocking forward and reverse control circuit

28. Double interlock control circuit

29. Automatic sequence control circuit

30. Three-phase asynchronous motor manual sequence start

31. Asynchronous motor Y-Δ control circuit

32. Button interlocking three-phase asynchronous motor forward and reverse control circuit

33. Contactor interlocking three-phase asynchronous motor forward and reverse control circuit

34. Double interlocking three-phase asynchronous motor forward and reverse control circuit

35. One-way decompression start and reverse brake control circuit

36. Asynchronous motor reverse connection brake control circuit

37. Automatic shuttle control circuit

38. Forward and reverse jog, start control circuit

39. Automatic reciprocating control circuit with jog

40. Asynchronous motor self-locking control circuit

41. Asynchronous motor unidirectional jog and start control circuit

42. The control circuit of the contactor to control the two-speed motor

43. The control circuit of the time relay to control the two-speed motor

44. PLC electrical control and machine tool circuit transformation

45. PLC controlled three-phase squirrel cage asynchronous motor jog control and self-locking circuit

46. PLC controlled three-phase squirrel cage asynchronous motor with delay forward and reverse circuit

47. PLC controlled three-phase squirrel cage asynchronous motor interlocking forward and reverse circuit

48. PLC controlled three-phase squirrel-cage asynchronous motor Y/Δ conversion starting circuit

49. Three-phase squirrel cage asynchronous motor controlled by PLC reversely connects the brake circuit

50. PLC controlled automatic return line

51. PLC controlled two start and stop circuits

52. PLC controlled three-phase squirrel cage asynchronous motor sequence start circuit

53. Electric circuit of electric hoist controlled by PLC

54. Comprehensive application of PLC, frequency converter and touch screen

55. Inverter function parameter setting and operation

56. Inverter stepless speed regulation

57. The inverter controls the motor forward and reverse

58. External terminal jog control

59. Multi-speed selection frequency conversion speed regulation

60. External analog quantity (voltage/current) frequency conversion speed regulation

61. Instantaneous power failure start control

62. PID frequency conversion speed control

63. PLC object training (stepping motor positioning, etc.)

64. PLC controls the motor forward and reverse rotation of the external terminal of the inverter

65. PLC-based program operation control

66. Based on PLC analog quantity control frequency conversion open loop speed regulation

67. Open loop speed regulation of frequency converter based on PLC communication mode

68. Speed closed-loop positioning control based on PLC communication mode

69. Inverter closed loop speed regulation based on PLC analog quantity mode

70. PLC and man-machine interface touch screen communication control

71. PLC, man-machine interface touch screen and inverter communication control

72. PLC and man-machine interface touch screen digital speed control

73. PLC and man-machine interface touch screen analog speed control

74. Comprehensive maintenance training for electrical equipment

75. C6140 type lathe electrical circuit operation training

76. C6140 type lathe circuit fault detection and maintenance

77. X62W universal milling machine electrical circuit operation training

78.X62W universal milling machine circuit fault detection and maintenance

FAQ

Q1. What other services can Dolang provide besides teachingequipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.