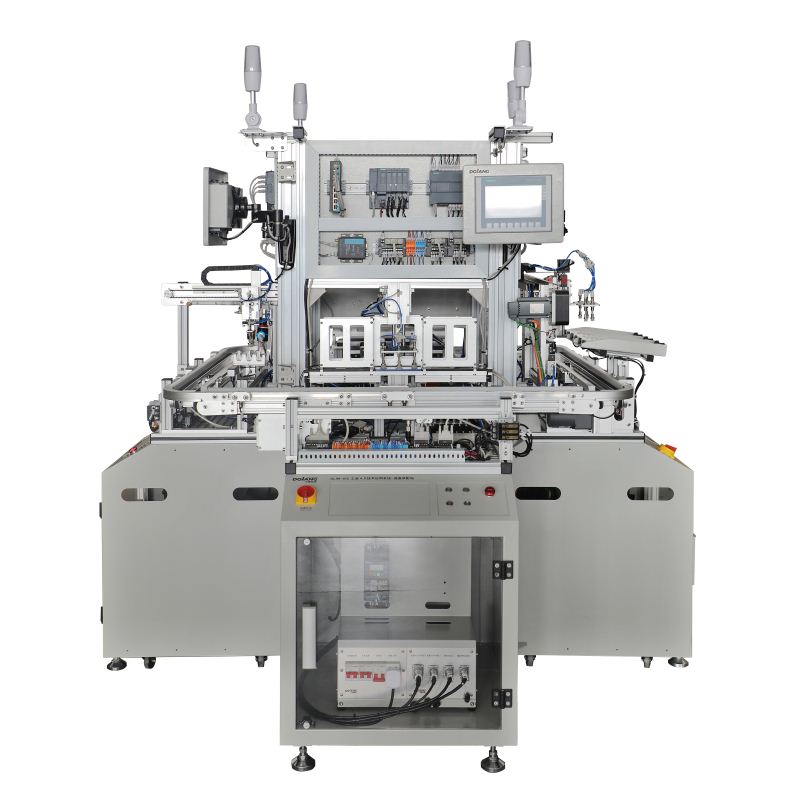

DLIM-412 Industrial 4.0 Technology Application Training System

- Dolang

- China

- 40-60 days

DLIM-412 Industrial 4.0 Technology Application Training System is one engineer teaching system following the latest industrial 4.0 technology, it may be used for TVET vocational school to realize training projects like MOUDLEBUS communication between PLC and RFID; Profinet communication between PLC and PLC;Communication between MES and PLC; Application of bus communication technology;Application of motor drive technology;Mechatronics collaborative simulation: mechanical interference, mechanism kinematics etc

1. Overview

DLIM-412 Industrial 4.0 Technology Application Training is engineer teaching equipment follwing the traned of "Industry 4.0" (the "fourth industrial revolution"), also known as "smart production" , is the interpretation of information physical integration, which completes the whole process of perception, communication, implementation and decision-making, including five categories: resource elements, interconnection, system integration, information integration and emerging business types, and guides enterprises to use digital, networked and intelligent technologies to develop towards model innovation. Through the introduction of information and communication technology (ICT) , collect, share and use production data information in different ways, realize the diversification and personalization of products and services, shorten the response time of production process, reduce production time and cost, so as to continuously improve industrial productivity.

2. Technical parameters.

1. Working power supply: AC220V ± 10%, 50Hz,

2. Rated power: 2KW

3. Floor area size: overall layout size: about 2100 * 2100 * 1780mm (L) × W × H )

4. Working environment: temperature 5 ℃ - + 40 ℃, relative humidity < 85% (25 ℃)

5. Safety protection: it has multiple protections of short circuit, overload, audible and visual alarm light and emergency stop

6. PLC: Siemens series

3. Training projects

1. MOUDLEBUS communication between PLC and RFID;

2. Profinet communication between PLC and PLC;

3. Communication between MES and PLC;

4. Application of HMI and stepping;

5. Application of bus communication technology;

6. Application of industrial automation network;

7. Application of PLC technology;

8. Application of motor drive technology;

9. Application of motion control system;

10. Digital 3D model construction and layout;

11. PLC virtual debugging;

12. 3D digital production line layout;

13. Mechatronics collaborative simulation: mechanical interference, mechanism kinematics verification, mechanism dynamics verification;

14. Application of MES system.

15.SQL database application

16.Heidi SQL data application

17. Wireshark software technology application

18. RFID application technology

19. Network security technology: network planning, network wiring, firewall, gateway settings, etc.

20. Logistics Technology

21. Internet of Things Technology

22. APP development and application technology

23. Web Development and Application

24. C# or Java, Javascript software application