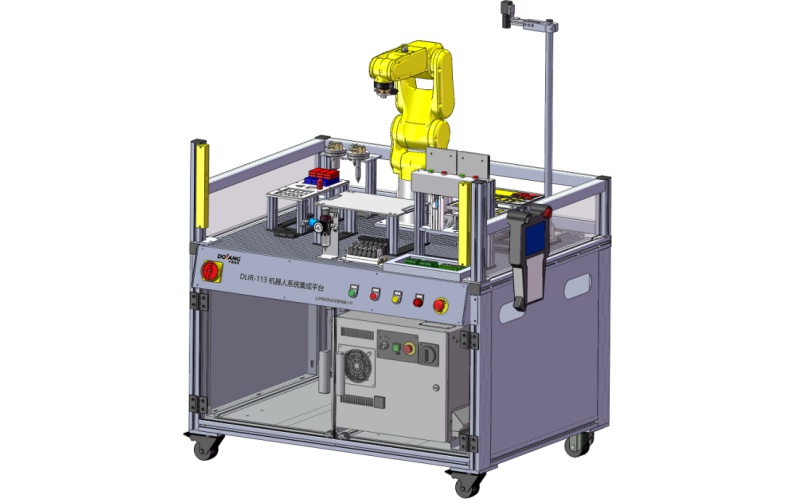

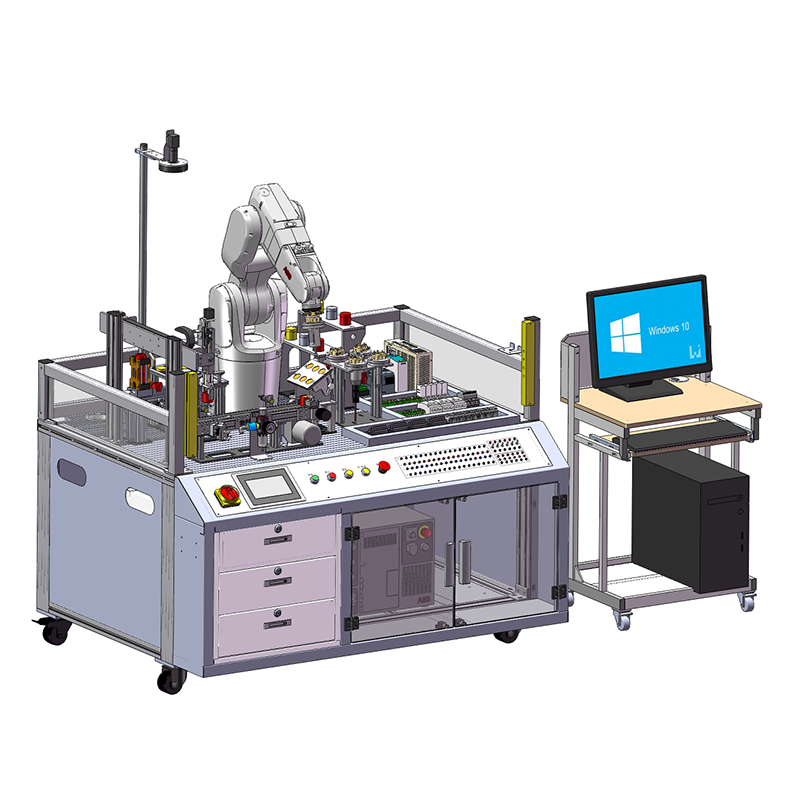

DLIR-257-1 Industrial Digital Twin System

The DLIR-275 industrial digital twin system simulates a highly automated smart factory, which includes industry 4.0 technology and advanced manufacturing concepts. The smart production line includes production processes and processes such as feeding, filling, sealing and storage, and is equipped with digital twins The simulation workstation is used for the expansion, design and virtual commissioning of subsequent production lines. The system software includes PLC programming software, MES manufacturing execution system, industrial digital twin development platform and other software. Students can learn and master relevant professional skills through the localization of physical equipment systems.

Model: DLIR-257-1 Industrial Digital Twin System

Power and voltage:(customized):AC220V±10%, 50Hz/60Hz

Dimension: 3500mm*2000mm*2000mm (L*W*H)

Warranty: 1 year

Delivery time: 45 days

Students using this system can learn to master the following skills:

1) Sensor detection technology: including optical fiber sensors, photoelectric sensors, inductive sensors, load cells, displacement sensors, etc. commonly used in industry.

2) Motor drive technology: including servo motors, stepping motors, AC motors and drivers, etc. Students can recognize, understand and master the use of various motors on this device.

3) Siemens PLC technology: trainees can practice PLC wiring, programming, debugging, and fault diagnosis skills on this device.

4) RFID technology: RFID installation, reading and writing, reset, communication and adjustment.

5) Configuration technology: students can learn programming, communication and optimization skills of configuration software on this device.

6) System maintenance and fault detection technology: students can learn the content and methods of daily maintenance of mechatronic equipment, as well as common fault analysis and troubleshooting methods. And the fault pre-diagnosis function can be realized through the digital twin technology.

7) MES manufacturing execution management system: users learn various management functions such as enterprise manufacturing data management, planning and scheduling management, production scheduling management, project kanban management, production process control, underlying data integration analysis, and upper layer data integration and decomposition through MES software.

8) Logistics transmission technology: The platform not only includes transshipment, handling, assembly, storage technology, but also identification, data transmission tracking and other technologies.

9) Digital twin technology: You can learn how to use the industrial simulation development platform to carry out the layout, design, debugging and optimization of virtual factories and production lines.