DLQD-DP401 Double-sided Electric pneuamtic Training System PLC controlled pneumatic workbench for vocational educaiton

- Dolang

- China

- 30-60DAYS

·Meet the school experiment requirements

·Basic and teaching training system that meets actual application needs

·Sturdy and stable equipment structure

·Low noise operation

·Clear layout and intriguing design

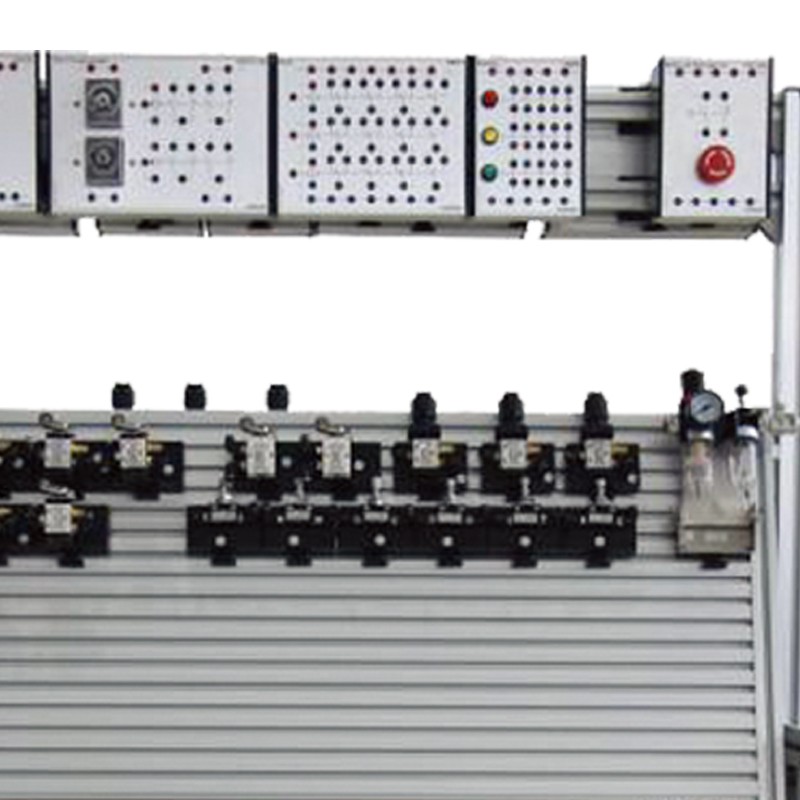

DLQD-DP401DLQD-DP401 Double-sided Electric pneuamtic Training System PLC controlled pneumatic workbench for vocational educaiton

Equipment Overview

The DLQD-DP401 Double-sided Electric pneuamtic Training System PLC controlled pneumatic workbench for vocational educaiton is designed in accordance with the requirements of modern pneumatic teaching and experimentation, based on the content of "Hydraulic and Pneumatic Transmission", "Pneumatic Control Technology", and other general teaching materials. In addition to the conventional pneumatic basic control loop experiment, the system can also carry out simulated pneumatic control technology application experiment, pneumatic technology course design, etc. At the same time, the device is also equipped with a programmable controller (PLC), which allows students to complete an intelligent control loop design. Therefore, the device is a typical experimental equipment with perfect combination of electromechanics.

The system is suitable for the teaching experiments of "hydraulic and pneumatic transmission", "pneumatic control technology" and other related courses in mechanical engineering, mechatronics and automation in colleges, technical schools, and vocational schools. It can also be used as a machine The comprehensive experimental platform integrated with electricity and gas can comprehensively reflect the most advanced pneumatic technology and mechanical, optical, electrical, sensor technology used in the factory's mechatronics manufacturing process, as well as modern PLC control technology. Through operation experiments and course design, students can accurately grasp the structure of pneumatic components, control principles and design methods of pneumatic circuits. In addition, there are a large number of complete sets of components to choose from and upgrade! It has strong scalability and practicality. The device adopts a combined modular structure, and students can combine pneumatic circuits and electrical control systems by themselves, with strong practical operation functions. It integrates various industrial pneumatic components, relay control technology, PLC technology, and configuration simulation technology. The device has the following characteristics:

·Satisfy school experiment requirements

·Basic and teaching training system that meets actual application needs

·Sturdy and stable equipment structure

·Low noise operation

·Clear layout and intriguing design

Technical Parameters

Power supply: AC 220V 50HZ

Air compressor: Power supply: AC 220V±10% 50Hz, motor power: 600W

Nominal volume: 9L Rated output pressure 0.7MPa, noise level: 66dB

Training Content

1. Pneumatic basic control loop experiment;

2. Single-acting cylinder automatic control;

3. Automatic control of double-acting cylinder;

4. Application of relay control technology;

5. Application of PLC control technology;

6. Other types of pneumatic circuits such as comprehensive and expandable experiments.

Examples of basic pneumatic experimental circuits:

1. Reversing circuit of single-acting cylinder;

2. Reversing circuit of double-acting cylinder;

3. Single-acting cylinder speed control loop;

4. One-way speed regulation circuit of double-acting cylinder;

5. Double-acting cylinder two-way speed control circuit;

6. Speed switching circuit;

7. Buffer circuit;

8. Secondary pressure control loop;

9. High and low voltage conversion circuit;

10. Delay loop;

11. Overload protection circuit;

12. Interlock circuit;

13. Single cylinder single reciprocating control loop;

14. Single cylinder continuous reciprocating action circuit;

15. Multi-cylinder sequence action circuit;

16. Double cylinder synchronous action circuit;

17. Or gate type shuttle valve application circuit;

18. The application circuit of the double pressure valve with the gate;

19. Fast exhaust valve application circuit;

20. Application of magnetic induction proximity switch;

21. Application of sensors in control systems;

22. Relay control circuit;

23. Pneumatic circuit and system controlled by PLC.

FAQ

Q1. What other services can Dolang provide besides teachingequipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.