DLRB-541D Candy Packaging And Handling System Of Industrial Robot control technologyMPS Training equipment

- Dolang

- China

- 30-60 days

The system is mainly used to demonstrate the sorting and packaging process of candy, including raw materials, visual inspection, sorting, assembly and handling and palletizing storage

provide a strong foundation support for the promotion of industry 4.0. Industrial robot packaging and handling system,

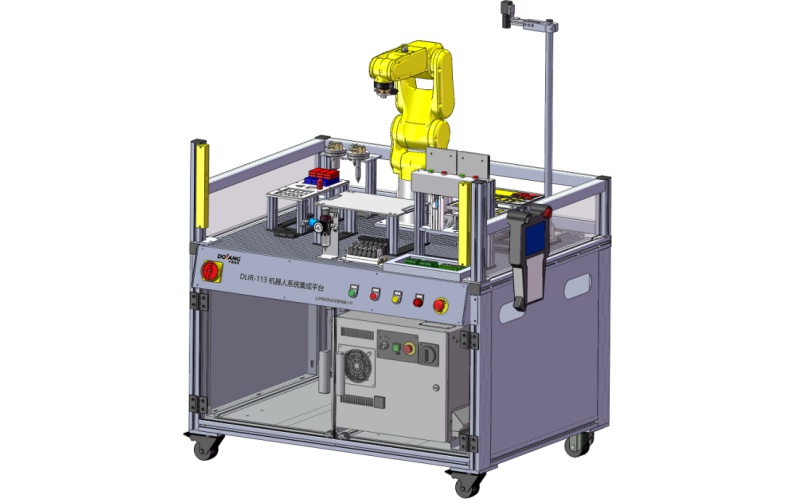

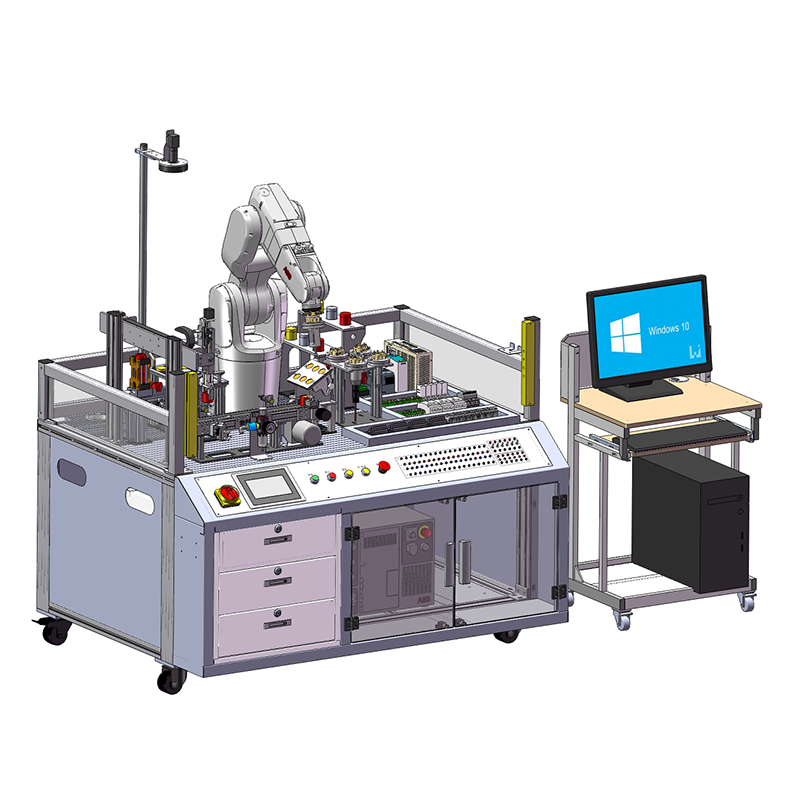

DLRB-541D Candy Packaging And Handling System Of Industrial Robot control technologyMPS Training equipment

Equipment Overview

DLRB-541D Candy Packaging And Handling System Of Industrial Robot control technologyMPS Training equipment: The system includes five working units (workstations): handling / palletizing station, loading station, sorting station, packing stations, U-type transmission stations,image process .

The system is mainly used to demonstrate the sorting and packaging process of candy, including raw materials, visual inspection, sorting, assembly and handling and palletizing storage; can correspond to the real industry 3.0 product processes: raw materials, machinery and equipment, factories, transport and sales, provide a strong foundation support for the promotion of industry 4.0. Industrial robot packaging and handling system, including the logistics packaging, handling, sorting and other industrial processes, covering electrical control technology, industrial robot technology, programmable controller technology, modern network information management technology and many other technologies;

Technical Parameters

Working power: three-phase five-wire 380V ± 5% 50Hz/60Hz

Safety protection: leakage protection, overcurrent protection, fuse protection

Robot parameters: four-axis, six-axis, parallel industrial robots

Ambient temperature: -10 ℃ ~ 50 ℃

Relative humidity: ≤85%

Training Content

1.Installation and wiring of 4 - axis Industrial Robot Body and Controller.

2. 4 - axis Industrial Robot initialization and Parameter Recovery.

3. IO Communication between 4 axis industrial robot and PLC.

4. 4 axis industrial robot IO wiring.

5. 4 axis industrial robot installation and wiring.

6. Programming and Debugging of 4 Axis Industrial Robot.

7. Installation wiring of parallel type industrial robot body and controller.

8. Initialization and parameter recovery of parallel industrial robot

9. IO communication between parallel type industrial robot and PLC.

10. Parallel type industrial robot IO wiring.

11. Parallel industrial robot installation and wiring.

12. Parallel type industrial robot programming and debugging.

13. Handling unit installation wiring and debugging

14. Unpacking loading unit installation wiring and debugging

15. Visual inspection and sorting unit installation wiring and debugging

16. Installation wiring and debugging of U-type transport unit.

FAQ

Q1. What other services can Dolang provide besides teaching equipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.