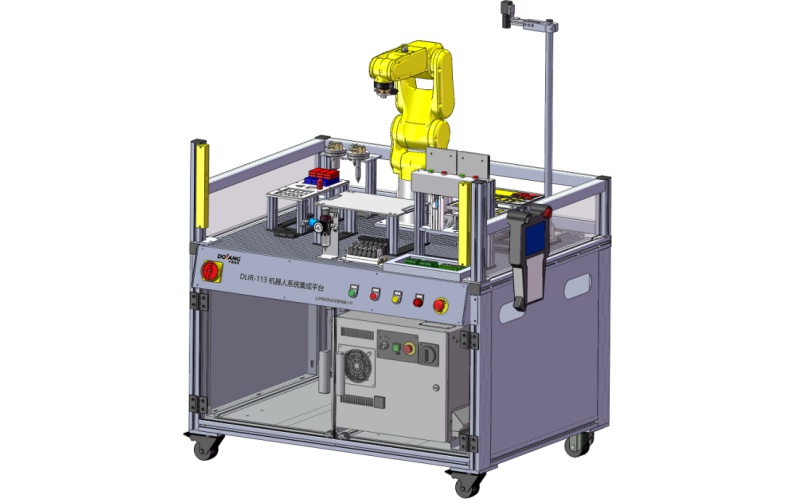

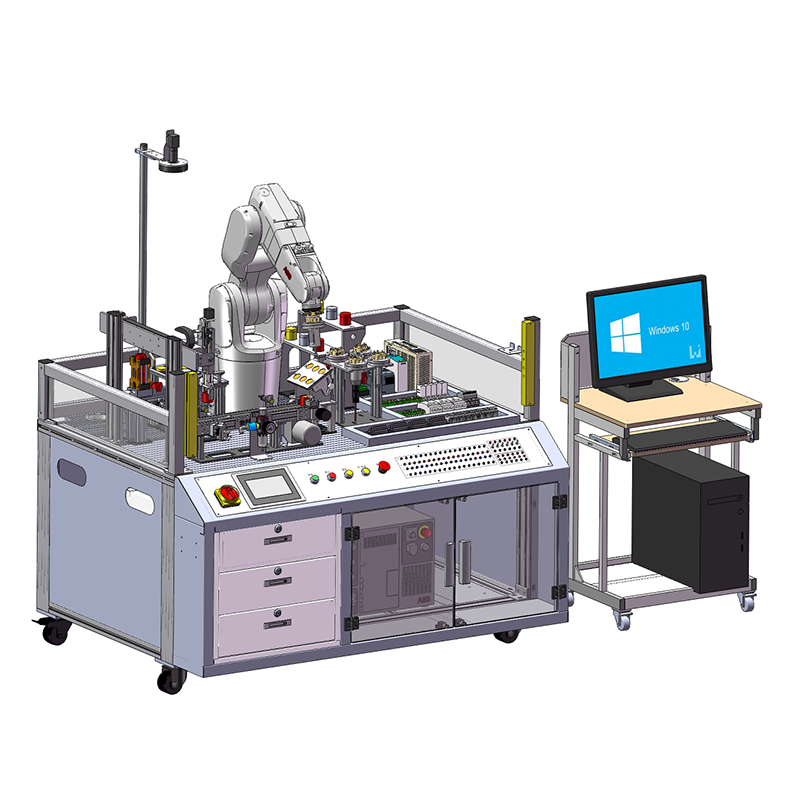

DLRB-801 Didactic Flexible Manufacturing Training System Industrial Robotics Training Equipment for Technical Vocational Education

- Dolang

- China

- 30-60DAYS

DLRB-801 Didactic Flexible Manufacturing Training System Industrial Robotics Training Equipment mianly designed for technical vocational education training. The training system can be used to demonstrate the production and assembly process of parts, including feeding, testing, processing and warehousing.and for sensor training,for the training of electrical control system, for motor drive technology training, for industrial robot training.

DLRB-801 Didactic Flexible Manufacturing Training System Industrial Robotics Training Equipment

The Didactic Flexible Manufacturing Training System is divided into eight work units (workstations): CNC lathe unit, CNC milling machine unit, manipulator unit, material storage unit, manipulator assembly unit, visual detection unit, RFID radio frequency detection unit and annular conveying unit.

Equipment Overview

The Flexible manufacturing system is mainly used to demonstrate the production and assembly process of parts, including feeding, testing, processing and warehousing.

The Flexible manufacturing system can be used for sensor training, including photoelectric sensor, optical fiber sensor, inductive sensor, capacitive sensor, Hall sensor, etc. The trainees can understand each sensor and master the usage of each sensor.

The Flexible manufacturing system can be used for the training of image detection technology. Students can understand the image detection equipment, master the use of image detection equipment, and practice the programming of image detection software.

The Flexible manufacturing system can be used for the training of electrical control system. The electrical part drawings are designed according to the industrial standards. Students can learn the circuit principle analysis, PLC I / O address check and new equipment circuit connection analysis methods on the equipment.

The Flexible manufacturing system can be used for motor drive technology training, including DC motor, single-phase motor, three-phase motor, stepper motor and driver, servo motor and driver, etc. students can understand the motor and master the use method of each motor on the equipment.

The Flexible manufacturing system can be used for industrial robot training. The trainees can understand the real industrial robot, learn how to use the industrial robot, and practice the software programming of industrial robot.

Technical Parameters

1. Input power: three phase five wire 380V ± 10% 50HZ 2. Leakage protection: I △ n ≤ 30mA, t ≤ 0.1s 3. Control power supply: DC24 V 4. Emergency stop button, power supply indication, power supply indication 5. Protection of power failure and power failure 6. Working environment: temperature - 10 ℃~ + 40 ℃, relative humidity 35% ~ 65% (25 ℃), altitude < 4000m 7. Device capacity: ≤ 5KVA 8. The pressure range of gas source is 0.4 ~ 0.6MPa 9. Size: 7500x5000x2000mm, height of operation table is 750mm |

Training Content

5.1 material storage unit

Complete the training of magnetic sensor adjustment

Complete servo motor control training;

Complete X-axis control training;

Complete Y-axis control training;

Complete x, Y axis control training;

Complete z-axis control training;

Complete the training of workpiece automatic storage control;

Complete the training of automatic stock out control of workpieces;

5.2 transmission unit of main control loop line

Practice the installation of PLC software, TIA software installation training;

Complete PLC software programming and hardware configuration training

Complete PLC software programming training

Practice the upper computer software installation training;

Practice practical training of upper computer software;

Practice the upper computer configuration training;

Practice PC communication training;

Complete fieldbus training;

Complete the signal acquisition training for each slave station;

Practice the application training of network information processing technology in the industry;

Complete the network address setting training;

5.3 industrial robot unit

Complete the photoelectric sensor adjustment training

Complete servo motor control training;

Complete the industrial robot programming control training;

Complete the practical training of servo motor driving industrial robot to grasp the workpiece;

5.4 CNC lathe unit + CNC milling machine unit

Operation of CNC machine tools

5.5 NC system composition, connection and debugging training

CNC integrated test bench connection and debugging training;

The structure of numerical control comprehensive test bed;

Basic connection of numerical control device;

Understanding and connection of CNC system interface;

Selection and application of sensors in CNC system;

Design principle of electrical control system of CNC machine tool;

Parameter setting and experiment of numerical control device;

CNC machine tool operation debugging training;

Servo system debugging and operation training;

5.6 manual programming and simulation processing training

NC machine programming and simulation processing;

Master the structure, format and instruction system of NC program;

Understand the basic operation of each system;

Understand the basic machining process of CNC machine tools.

NC machine programming and operation training

Master the program editing of NC machine tools;

Master the basic operation of CNC machine tools;

The skill application of CNC machine tool system function;

Clamping and machining of parts in NC machining;

Fault setting, diagnosis and elimination

Basis of NC milling machine programming

NC milling machine programming operation and processing examples

5.7 manipulator assembly unit

Complete the training of magnetic sensor adjustment

Complete the photoelectric sensor adjustment training

Complete stepper motor control training

Complete servo motor control training

Complete the practical training of workpiece assembly

5.8 image detection unit

Complete the photoelectric sensor adjustment training

Complete the working principle training of visual recognition system;

Complete the training of focus adjustment;

Finish the practical training of dimming;

Complete the sensor trigger signal training;

Complete the practical training of the capture process;

Complete the training of debugging imaging principle with software;

Complete the data processing training of PLC receiving visual signal;

5.9 RFID system unit

Complete the photoelectric sensor adjustment training

Complete the working principle training of RFID system;

Complete the RFID system to write information training;

Complete the RFID system to read information training;

Complete the sensor trigger signal training;

Complete the data processing training of PLC receiving RFID signal;

FAQ

Q1. What other services can Dolang provide besides teachingequipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.