DLWD-ETBE12D-II Advanced Electrical Maintanenace Training Set of Vocational Education Equipment

- Dolang

- China

- 30-60DAYS

The electrical control circuit components are installed on the mounting board as a hanging board, which is convenient to operate and replace, which is convenient for expanding functions or developing new training; the selection of operating content is typical, practical and scientific....

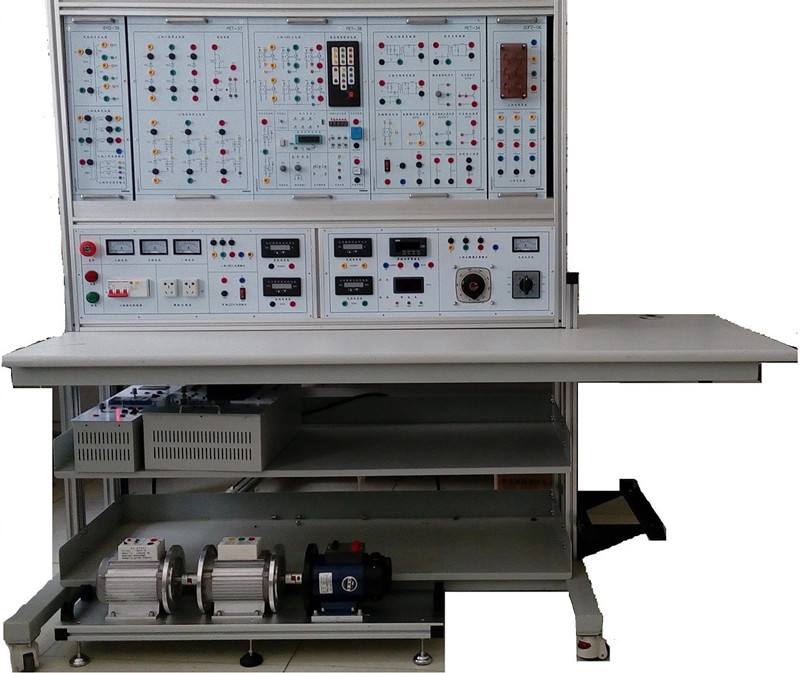

DLWD-ETBE12D-II Advanced Electrical Maintanenace Training Set of Vocational Education Equipment

Equipment Overview

1. The electrical control circuit components are all installed on the mounting board as the hanging board, which is convenient to operate and replace, which is convenient for expanding functions or developing new training; the selection of operation content is typical, practical and scientific.

2. The training platform adopts three-phase five-wire access to ensure the stable and reliable grounding of the training equipment, and the area is small, saving housing and reducing infrastructure investment;

3. The control circuit and specially designed small motor for skill training can simulate all kinds of electric drive systems in the factory, and can meet the requirements of maintenance electricians' installation, debugging, fault analysis and troubleshooting skills;

4. All the components of the relay contact control circuit training are led to the terminals through wires. Students only need to wire on the terminals when wiring, which is beneficial to protect the components; during the training, the wires are routed through the trunking to perform the process Wiring training;

5. Electrical components such as contactors and thermal relays adopt well-known domestic and foreign brands to ensure the quality and performance of the equipment;

6. Equipped with voltage-type leakage protector and current-type leakage protector to ensure the safety of the operator; each power output has functions such as monitoring and short-circuit protection, when misoperation occurs during training or short-circuit due to wiring errors , The device can automatically protect to avoid burning the fuse and damaging the electrical appliances, ensuring the smooth progress of the training;

7. The control screen is also equipped with a timer and alarm recorder (service manager), which provides a unified standard for the assessment of students' experimental skills;

8. The connection between the training circuit and the power supply of the device is through the safety socket and the high-reliability sheath structure pistol plug-in wiring, which is safe and fast;

9. The device is equipped with a three-phase power output short-circuit soft cut-off protection function, which prevents short-circuit damage to components due to incorrect wiring or misoperation during the training. At the same time, it can ensure the smooth progress of the training and save the cost of training.

Technical Parameters

1. Input voltage Three-phase five-wire system 380V±10% 50HZ

2. Working environment The ambient temperature range is -5~40℃

3. Device capacity AC<1.5KVA

DC: Excitation power supply<0.5A

Armature power supply<2A

4. Overall dimensions length×width×height=1810x720x1620mm3

Technical parameters of training platform:

1) Input voltage Three-phase five-wire system 380V±10% 50HZ

2) Working environment The ambient temperature range is -5~40℃, relative humidity<85% (25℃), altitude<4000m

3), device capacity AC <1.5KVA

5. Total power supply control, with leakage protection function, when the leakage current reaches 30mA, the protection device will act.

6. There are 3 450V pointer type AC voltmeters for power grid voltage indication.

7. AC power supply:

(1) Provide three-phase power output

(2) 0~220V/2A adjustable AC power output

(3) Transformer AC output; the equipment has an emergency stop button, press it to immediately cut off the three-phase power output.

8. DC power supply: (1) Provide 1.25~30V/2A adjustable DC power supply, and equipped with DC meter display, accuracy level 1, (2) Provide 0~190V/2A adjustable DC power supply.

9. Digital instrument (1) AC digital voltmeter: accuracy 1.0; measuring range 0~450V (3) AC digital ammeter: measuring range 0~5A, accuracy 0.5 grade, three and a half digital display; (4) DC One digital voltmeter: measuring range 0~450V, three-and-a-half digital display, input impedance of 10MΩ, precision 0.5; (5) One DC digital ammeter: measuring range of 0~5A, three-and-a-half digital display, precision 0.5 .

10. Rectifier diodes Four 1N5408 rectifier diodes are provided at the four stations for rectification and motor experiments.

Training Content

1. Single-phase start-stop control circuit

2. Asynchronous motor jog control circuit

3. Two-place control circuit of asynchronous motor

4. Asynchronous motor interlocking forward and reverse control circuit

5. Double interlock control circuit

6. Automatic sequence control circuit

7. Manual sequence start

8. Asynchronous motor star and delta control circuit 9. Asynchronous motor energy consumption braking control circuit

10. Button interlocking three-phase asynchronous motor forward and reverse control circuit 11. Contactor interlocked three-phase asynchronous motor forward and reverse control circuit 12. Double interlocked three-phase asynchronous motor forward and reverse control circuit

13. One-way decompression start and reverse brake control circuit

14. Asynchronous motor reverse connection brake control circuit

15. Automatic round-trip control line

16. Forward and reverse jog, start control circuit

17. Automatic reciprocating control circuit with jog

18. Asynchronous motor self-locking control circuit

19. Asynchronous motor single-phase jog, start control circuit

20. Three-phase asynchronous motor stator series resistance decompression start manual control circuit

21. Three-phase asynchronous motor stator series resistance decompression start automatic control circuit

22. The time relay controls the starting circuit of the two-speed motor

23.CA6140 lathe control circuit

24. Electric hoist control circuit

25.X62W milling machine control circuit

26.T68 boring machine control circuit

27. Inspection and elimination of common faults in the electrical control circuit unit of the CA6140 lathe (16 fault points, automatic fault setting).

28. Inspection and elimination of common faults in the electrical control circuit unit of X62W milling machine (16 fault phenomena, automatic fault setting)

29. Inspection and elimination of common faults of electric control circuit unit of electric hoist (16 fault phenomena, automatic fault setting)

30. Inspection and elimination of common faults of T68 boring machine electrical control circuit unit (16 fault phenomena, automatic fault setting)

31. Starting of separately excited DC motor

32. Speed regulation of separately excited DC motor

33. Positive and negative rotation of separately excited DC motor

34. Braking of separately excited DC motor

35. DC motor mechanical characteristics test

36. Reversal control circuit with dynamic braking

37. Control circuit of excitation reverse connection brake

38. AC motor mechanical characteristic test;

39. Socket and a switch control a lamp (incandescent lamp, fluorescent lamp + two-pole leakage switch)

40. Two double switches control one lamp (incandescent lamp, fluorescent lamp + two-pole leakage switch)

41. Three switches control one lamp (incandescent lamp, fluorescent lamp + two-pole leakage switch)

42. Wiring of fluorescent lamp circuit

43. Voice-activated switch controls the wiring of the incandescent lamp circuit

44. Single-phase watt-hour meter direct wiring circuit

45. Wiring circuit of single-phase watt-hour meter via current transformer

46. Wiring circuit of voltmeter and ammeter

47. The voltmeter of the universal transfer switch measures the three-phase voltage wiring

48. A current transformer is used for the control circuit wiring of a single-phase loop

49. Measuring circuit of three-phase power factor meter

50. Wiring circuit of three-phase four-wire active watt-hour meter

51. Wiring circuit of three-phase four-wire active watt-hour meter via current transformer

FAQ

Q1. What other services can Dolang provide besides teachingequipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.