industrial

-

Hot

Digital twin training system

DLIM-DT01B Digital twin technology application platform Using digital twin technology application platform, a virtual simulation system with actual interactive function is created according to the requirements. The simulation system can realize the physical performance, mechanical structure and action function consistent with the actual environment. It can make the mechanical design and electrical design develop in parallel on the simulation system, and eliminate the gap period in the traditional development process. The simulation system is not only a simple animation scene, but also can interact with the actual control equipment, receive control instructions and feedback signals from sensors, etc. during the simulation process, it can timely discover various problems in the operation of the equipment under program control and carry out optimization, so as to improve the design efficiency and reduce the cost and risk. In response to the above situation, the State Council issued notice on Issuing the plan for the implementation of the national vocational education reform (Guo Fa [2019] 4), pointing out that we should adapt to the development demand of "Internet plus occupation education", improve the teaching methods and methods with modern information technology, and promote the construction and application of virtual learning network occupation space, and complement and expand the offline practical training teaching activities.

vocational education vocational training system international cooperation indsutrial 4.0 training systemEmail Details -

DLZL-WAC01 water-cooled central air conditioning training device

The central air conditioning training and assessment device is a multifunctional system integrating teaching, training and assessment. It provides students with a learning platform close to the actual working environment through highly simulated hardware facilities and advanced software technology, which helps to cultivate them into qualified refrigeration technology professionals.

Email Details -

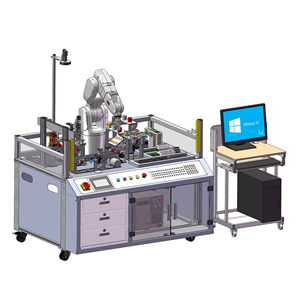

DLIR-174 Industrial Robot Operation and Programming Application System

The skills students can learn and master using this platform include sensor detection technology, visual detection technology, electrical control technology, stepper drive technology, servo drive technology, industrial robot technology, PLC technology, configuration technology, production line process design, system maintenance and Fault detection technology, offline programming simulation technology, industrial Ethernet communication technology, etc.

Email Details -

DLIOT-B114B Industrial Automation Network Integrated Training System

The DLIOT-B114B industrial automation network training platform is developed based on Siemens' fully integrated automation PLC control system. This industrial automation training platform is a comprehensive training device developed for higher education and vocational and technical education. It is suitable for teaching in mechatronics, automation and other majors in various vocational schools (colleges) and for those engaged in related professional technologies. Practical training of personnel. This system can not only be used as an automated and networked teaching and training system, but can also be combined with subsystems to form a networked classroom.

Email Details -

DLIOT-B114A Industrial Automation Network Integrated Training System

The DLIOT-B114A industrial automation network training platform is developed based on Siemens' fully integrated automation PLC control system. This industrial automation training platform is a comprehensive training device developed for higher education and vocational and technical education. It is suitable for teaching in mechatronics, automation and other majors in various vocational schools (colleges) and for those engaged in related professional technologies. Practical training of personnel. This system can not only be used as an automated and networked teaching and training system, but can also be combined with subsystems to form a networked classroom.

Email Details -

DLIOT-A241 Industrial Automation Network Integrated Training System

1. Realize the interconnection of production and manufacturing equipment. Communication network connects field equipment, controllers, HMI, monitoring systems and enterprise management systems. It is the transmission channel for information in industrial production systems and plays an important role in the stability and reliability of industrial production systems. 2. Cultivate professional industrial Ethernet and industrial Internet engineers. Through specialized training equipment to meet the needs of industrial development.

Email Details -

DLIOT-A231 industrial network programming and debugging application system

This system relies on modern industrial automation technology and uses many advanced technologies such as industrial Internet technology, edge computing technology, big data analysis, automatic control technology, and intelligent sensor technology to complete the programming and debugging functions of the industrial network system. "DLIOT-A231 Industrial Network Programming and Debugging Application System" is mainly composed of an industrial network control unit, an intelligent detection unit, and a computer desk;

Email Details -

DLDZ-IOT02 IoT Technology Comprehensive Application Platform

Introduction to the Internet of Things IoT application programming Industrial communication network; SCADA and data collection

Introduction to the Internet of Things IoT application programming Industrial communication network SCADA and data collectionEmail Details -

DLAI-323 AI Fusion Innovation Application Training Platform

The AI training platform is composed of high-performance computer, mobile terminal development platform, machine vision detection module, Harbot collaborative robot module, AGV, application scene simulation module and other systems. The software platform is based on Windows (Linux Ubuntu 18.04 is optional). Python, YOLOv5, OpenCV, PyTorch, TensorFlow and other modules are pre-installed.

Email Details