education equipment

-

DLJX-JXXT Mechanical Comprehensive Training System

The industrial maintenance training platform can carry out training projects such as the installation, use, maintenance and troubleshooting of mechanical transmission components. Project training through this system can enable students to further master and in-depth understanding of the theoretical knowledge of the course, and through practical training operations, improve the practical ability and the ability to analyze and solve problems.

virtual classroom equipment vocational education equipment TVET educational trainer technical engerring training deviceEmail Details -

DLJX-ZT501 Mechanical Assembly and Adjustment technology Comprehensive Training System of vocational education equipment

It mainly trains students to read and draw assembly drawings and parts drawings, basic fitter operations, parts assembly and adjustment, assembly quality inspection and other skills. Improve students' employability in the first-line process assembly and implementation of machinery manufacturing enterprises and related industries, installation, commissioning, maintenance and repair of electromechanical equipment, mechanical processing quality analysis and control, and grassroots production management.

vocational Training System vocational education equipment mechanical engineering laboratory equipment equipment for engineering educationEmail Details -

DLPCS-400 Filling Production Line Training System of vocational education equipment

This equipment combines the actual control requirements of the industrial site, and is oriented by modular design. It uses modern PLC control technology, sensor technology, optical technology, mechanical transmission principle technology, pneumatic technology, stepping control technology, and other elements to concentrate on the equipment. It reflects that it provides students with a broad training space and comprehensively and systematically masters the frontier knowledge of various disciplines. 1. Intuitiveness: The main equipment is installed directly exposed, and the equipment can be displayed in front of students more intuitively. 2. Miniaturization: The size of each station is 450mm×460mm×390 mm, which saves laboratory space and is easy to carry. 3. Modularization: Only through the network cable and simple mechanical docking, the assembly of a filling production line can be completed. Real-time is relatively strong. 4. Flexibility: Each station can operate independently or as a part of the production line. 5. Safety: Each station is equipped with an independent circuit breaker with short circuit and overload protection.

vocational education equipment factory automation production line mechatronics training system autoamtion control training systemEmail Details -

DLPLC-XCYD1 Small Car Motion Training Equipment PLC Training kit of vocational education equipment

1. The training device consist of the transmission and detection devices. 2. The electrical aspects consist of the DC gear motor, sensors, limit switches and other components, stroke range is 0.6 meters. 3. The system uses the computer simulation of modern information technology means, through the operation, simulation and simulation ,solve the previous professional training theory, experiment, practice and practical application problem. 4. Equipped with the configuration software, and provide the application guidance and application engineering examples.

PLC skills training kit vocational education equipment didactic plc Small Car Motion Training EquipmentEmail Details -

DLMPS-205 Modular Flexible Production System of vocational education equipment

The DLMPS-205 flexible manufacturing training system consists of a feeding station, a testing station, a handling station, an extrusion station and a sorting station. Each station is installed on a slotted aluminum substrate, and each station can be easily connected together to form an automatic Processing production line. Each station is a modular structure, each module is easy to build, disassemble and maintain, and each workstation can be combined at will.

vocational education equipment Logistics production line training industry 4.0 technology digital twins technologyEmail Details -

DLPCS-WDMK Temperature Control Module of vocational education equipment

The DLPCS-WDMK module panel of the control system is ready to install components. In combination with other modular control components, it enables the temperature control system to have different characteristics for construction and research.

vocational education equipment Temperature Control Module Process control training system process control didactic equipmentEmail Details -

DLGK-YL101 Pressure Process Control Trainer of vocational education equipment

1) Composition and structure characteristics 1. Simple structure: the overall structure has a skeleton and an executive part of the control cabinet, 2. Convenient operation, all operation, display and execution components are installed with external leakage, which is convenient for observation and operation 3. The overall frame is made of stainless steel to prevent the equipment from rusting 4. Only single-phase three-wire AC power supply can be put into use, and the floor space is small, saving housing and reducing infrastructure investment 5. The structure design of the open experimental object makes the experimental object intuitive and easy to understand. 6. The design of the hardware object fully considers the certainty of its mathematical model, which is consistent with theoretical textbooks. 7. The parameters and characteristics of the selected instruments meet the design requirements of the system, and the experimental results are ideal. 8. The disassembly and assembly of instruments and meters deepens students' understanding of engineering instruments and meters, especially the internal principles of devices. 9. A variety of control signals, a variety of control signals and control methods can be selected according to the experimental project 10. You can do DIY experiments; the training device can change the experimental objects and connection methods according to user requirements 11. Human-computer interactive experiment. The configuration software is used for interactive operation, that is, what you see is what you get, and data can also be collected. 2) Security protection 1. The power supply has protections such as leakage, overvoltage, overcurrent, and short circuit, which protect the safety of trainers. 2. Separation of water and electricity; that is, the control system and the execution system are separated, and all the wiring of the execution system is treated with waterproof measures 3) Configure teaching software

vocational education equipment Pressure Process Control Trainer vocational education teaching equipment Level control training systemEmail Details -

DLGK-53B Process Control Trainer of vocational education equipment

Boiler heating program control protection system 1. The boiler heating liner is equipped with a water level and liquid level protection device, and the control system can only control the heating after the water level reaches the specified height. 2. The power control switch of the electric heating tube adopts a key switch, which is easy to manage. Power protection measures 1. There is a current leakage protector. 2. The two-phase power supply has a fuse to prevent disconnection. Power start-stop control mode; Use the start-stop button to control the contactor to control the start and stop of the power supply. Leakage protection device and safety and safety commitment; Reliable protection functions of various power supplies and various instruments

vocational education equipment Process Control Trainer vocational education teaching equipment tvet equipmentEmail Details -

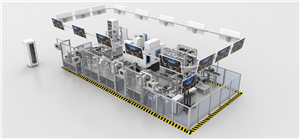

DLJS-X1806 Smart Manufacturing (photo frame) Automated Production Line System of vocational education equipment

1) The equipment is complete, which can be applied to the production, application and training of different processes such as storage, machining, marking, 3D printing, assembly testing, packaging and transshipment of three kinds of photo frames. 2) The process unit has a clear distribution and modular design, which is convenient for observation, debugging and teaching guidance in the production process. 3) Flexible connection between processes, which can adapt to the simultaneous production of various products and the adjustment and switching between product processes. 4) Fully automatic control, automatic production and demonstration according to the set parameters. 5) MES intelligent management, which can comprehensively manage the materials, finished products, production, equipment, personnel, orders, etc. 6) practical production design, can be applied to the actual production of photo frames. 7) Factory layout, high security, humanized control station to ensure full monitoring of equipment movements.

vocational education equipment Smart Manufacturing (photo frame) Automated Production Line System cyber intelligent manufacturing training system indsutrial 4.0 training systemEmail Details