mps

-

DLMPS-500C Modular Production System Industry 4.0 Training Kits from Dolang Didactic Equipment

Industry 4.0 MPS Learning Systems is designed for training in vocational skills and technical knowledge in the area of automation technology and mechatronics. Modular Systems for Mechatronics Training, used in technical vocational education training.(TVET) Advanced equipment technology: This equipment combines the actual control requirements of the industrial site, and the concentrated expression of various elements on the equipment provides students with a broad training space and comprehensively and systematically masters the frontier knowledge of various disciplines.

Email Details -

DLMPS-500B MPS Training System Modular Flexible Production Didactic Equipment

Dolang training system MPS series is designed for training in basic skills and specialist knowledge in the area of automation technology and mechatronics. MPS Learning Systems. Modular Systems for Mechatronics Training. MPS Modular. Production System. Model industrial automation systems at various levels. 1. Device intuitiveness 2. Networking of equipment 3. Advanced equipment technology: This equipment combines the actual control requirements of the industrial site, and the concentrated expression of various elements on the equipment provides students with a broad training space and comprehensively and systematically masters the frontier knowledge of various disciplines. 4. Combination of concentrated and divergent thinking: 5. Configurability: The device passes the configuration principle of each substation through the touch screen, and integrates the control of each station through the management of the main control unit. 6. The operability of the system: each work unit can be operated independently, that is, it can be connected to the Internet and work offline.

mps training system modular production training equipment mps trainer flexible production training systemEmail Details -

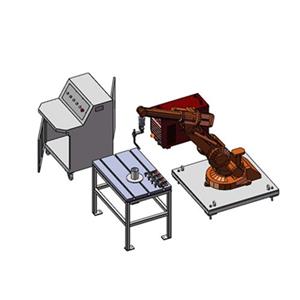

DLIM-512MS-3 Intelligent Manufacturing Robotic Educational Equipment- Industry 4.0 Training Equipment

Equipment Intuitive: The main equipment are used directly exposed form of installation, equipment can be more intuitive in front of students, shortening the students from the classroom to the industrial field transition and adapt time.

Robotic Educational Equipment intelligent manufacturing training equipment MPS Training equipment indsutrial 4.0Email Details -

DAFA-MPS-A Advanced Micro Multifunctional Mechatronics Training System for Skills Education Equipment

The training platform adopts special mould profiles and is treated by anodizing spraying. The structure is scientific and the appearance is beautiful. There is an adjuster at the bottom, which can be adjusted in height to ensure stability

Email Details -

DLRB-1410W Industrial Robot Welding FMS Training kit for Educational Training Equipment

The robot adopts an ultra-high-speed 6-axis operating mechanism with a working radius of 1.44m and a payload of 5kg. This generation of products optimizes the motor power and motion performance, making the overall performance better than similar competitive products.

Email Details -

DLPCS-400 Filling Production Line Training System of vocational education equipment

This equipment combines the actual control requirements of the industrial site, and is oriented by modular design. It uses modern PLC control technology, sensor technology, optical technology, mechanical transmission principle technology, pneumatic technology, stepping control technology, and other elements to concentrate on the equipment. It reflects that it provides students with a broad training space and comprehensively and systematically masters the frontier knowledge of various disciplines. 1. Intuitiveness: The main equipment is installed directly exposed, and the equipment can be displayed in front of students more intuitively. 2. Miniaturization: The size of each station is 450mm×460mm×390 mm, which saves laboratory space and is easy to carry. 3. Modularization: Only through the network cable and simple mechanical docking, the assembly of a filling production line can be completed. Real-time is relatively strong. 4. Flexibility: Each station can operate independently or as a part of the production line. 5. Safety: Each station is equipped with an independent circuit breaker with short circuit and overload protection.

vocational education equipment factory automation production line mechatronics training system autoamtion control training systemEmail Details -

Hot

DLMPS-800A MPS Machatronics Training system of Industry 4.0

1. Instictive: Main equipment use directly exposed installation form, the device can be more intuitive to show to students, shortening the adaptation time of students from the classroom to the industrial site. 2. Networking: PROFIBUS-DP acting as main line of network control system, the field device control layer act as a secondary line, the entire device follow the command of the supreme commander, while allowing each branch independently finish assigned tasks. The general control station is the leader of device and each unit is branch.3. Advanced technology: the device combines industrial practical control requirement, based on module design, use technologies like PLC control technology, sensor technology, optical technology, mechanical transmission technology, pneumatic technology, servo control technology, stepper control technology etc, provide extensive practical training to students. 4. Comprehensive: Master control station stands for focus thinking, and each sub-station stands for divergent thinking, they can work indepently and also can group management. 5. PC configuration: through the computer platform, combine various sub-station via configuration principle, each station will be controlled together by the teacher machine. 6. Easy to operate: Each work unit both can indepently operate and can be combined to network operation

Email Details -

DLRB-541D Candy Packaging And Handling System Of Industrial Robot control technologyMPS Training equipment

The system is mainly used to demonstrate the sorting and packaging process of candy, including raw materials, visual inspection, sorting, assembly and handling and palletizing storage provide a strong foundation support for the promotion of industry 4.0. Industrial robot packaging and handling system,

Email Details -

DLDS-500AR IR 4.0 MPS Training equipment vocational education equipment

This equipment is closely related to the development of occupation education in "industry 4". The Worldskills China competition "mechatronics" professional equipment. Sensor technology, pneumatic technology, control technology and robot technology are commonly used in automatic line.

Email Details